nuovo blog

PA6, noto anche come nylon 6, è una particella bianca lattiginosa traslucida o opaca, con caratteristiche termoplastiche, leggere, buona tenacità, resistenza chimica e durata, generalmente utilizzata in ricambi auto, parti meccaniche, prodotti elettrici ed elettronici, accessori di ingegneria e altri prodotti.

Le proprietà chimiche e fisiche del PA6 sono simili a quelle del PA66; tuttavia, ha un punto di fusione più basso e un ampio intervallo di temperature di processo. La sua resistenza agli urti e la solubilità sono migliori del PA66, ma è anche più igroscopico.

Poiché molte caratteristiche qualitative delle parti in plastica sono influenzate dall'igroscopicità, questo aspetto dovrebbe essere tenuto pienamente in considerazione quando si progettano prodotti che utilizzano PA6. Per migliorare le proprietà meccaniche del PA6, vengono spesso aggiunti numerosi modificatori. La fibra di vetro è l'additivo più comune e talvolta viene aggiunta gomma sintetica per migliorare la resistenza agli urti.

Plastica PA66ha un punto di fusione più elevato nei materiali in poliammide. È un materiale semicristallino - cristallino. PA66 può anche mantenere una forte resistenza e rigidità a temperature più elevate. La plastica PA66 ha ancora proprietà igroscopiche dopo lo stampaggio, la cui entità dipende principalmente dalla composizione del materiale, dallo spessore delle pareti e dalle condizioni ambientali. L'effetto dell'igroscopicità sulla stabilità geometrica deve essere considerato nella progettazione del prodotto. Per migliorare le proprietà meccaniche del PA66, vengono spesso aggiunti numerosi modificatori. Il vetro è l'additivo più comune e talvolta viene aggiunta gomma sintetica per migliorare la resistenza agli urti. La plastica PA66 è meno viscosa e quindi scorre bene (ma non così bene come la PA6).

PA66 (poliammide 66 o nylon 66), rispetto a PA6, PA66 è più ampiamente utilizzato nell'industria automobilistica, nella custodia di strumenti e in altri prodotti che richiedono resistenza agli urti e requisiti di elevata resistenza.

Ampiamente usato nella produzione di parti di macchinari, automobili, apparecchiature chimiche ed elettriche, come ingranaggi, rulli, pulegge, alberi del rullo, girante del corpo pompa, pala del ventilatore, tenuta ad alta pressione, sede della valvola, guarnizione, boccola, maniglie varie, telaio di supporto , strato interno del pacchetto di fili, ecc.

La materia prima plastica PA66 è un polimero cristallino opalescente traslucido o opaco, con plasticità. Densità 1,15 g/cm3. Punto di fusione 252°C. Temperatura di infragilimento -30°C. La temperatura di decomposizione termica è superiore a 350°C. Resistenza al calore continua 80-120°C, tasso di assorbimento d'acqua bilanciato del 2,5%. Resistente agli acidi, agli alcali, alla maggior parte dei sali inorganici acquosi, agli alogenuri alchilici, agli idrocarburi, agli esteri, ai chetoni e ad altri tipi di corrosione, ma facile al fenolo, all'acido formico e ad altri solventi polari. Ha un'eccellente resistenza all'usura, autolubrificazione ed elevata resistenza meccanica. Ma l'assorbimento d'acqua è maggiore, quindi la stabilità dimensionale è scarsa

PA66 è una varietà di serie PA con elevata resistenza meccanica e ampia applicazione. Grazie alla sua elevata cristallinità, ha un'elevata rigidità e resistenza al calore.

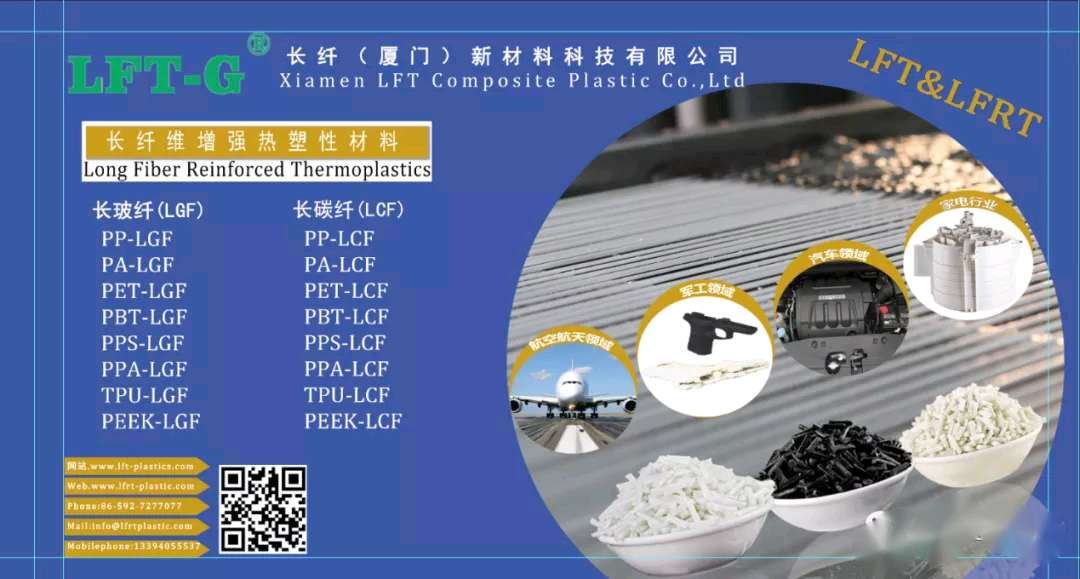

Xiamen LFT Composite Plastic Co., Ltd. è un'azienda di marca che si concentra su LFT e LFRT. Serie a fibra di vetro lunga (LGF) e Serie a fibra di carbonio lunga (LCF). L'LFT termoplastico dell'azienda può essere utilizzato per lo stampaggio a iniezione e l'estrusione LFT-G, nonché per lo stampaggio LFT-D. Può essere prodotto in base alle esigenze del cliente: 5~25 mm di lunghezza. I materiali termoplastici rinforzati con infiltrazione continua a fibra lunga dell'azienda hanno superato la certificazione del sistema ISO9001 e 16949 e i prodotti hanno ottenuto numerosi marchi e brevetti nazionali.