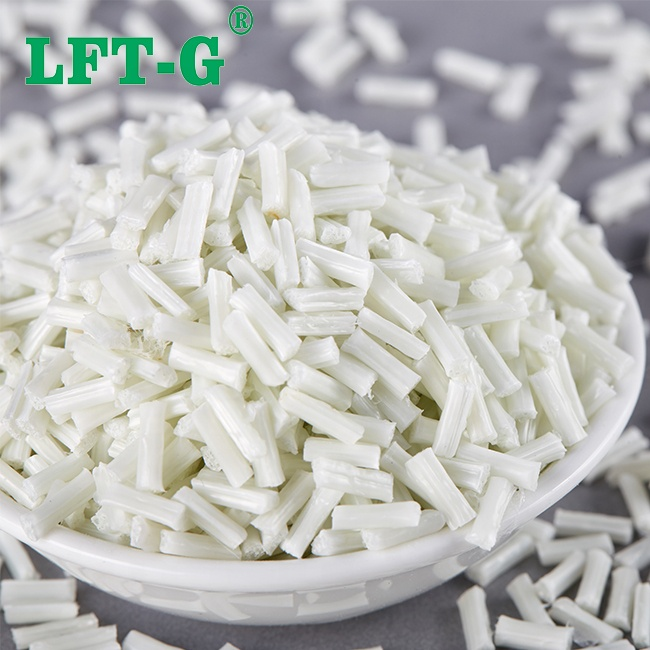

TPU LGF30 termoplastico a fibra lunga TPU LGF densità e TDS

Forma: lunghezza circa 12 mm, alta resistenza, alta tenacità

Vantaggio: più di 20 anni di esperienza nel prodotto in plastica rinforzata con fibra.

lft-g è un team guidato da professionisti che lavorano nel settore delle materie plastiche da quasi 20 anni. siamo specializzati in design, ricerca e sviluppo, fibra di vetro lungo su misura per i clienti; lunga fibra di carbonio; lunga e completa fibra di vetro e fibra di carbonio lunga; composito in fibra speciale. i materiali possono essere ampiamente utilizzati nel settore aerospaziale, automobilistico, militare; elettrodomestici;

√ Il primo schienale del sedile indipendente leggero della terza fila √ La soluzione aiuta le nuove auto a perdere il 30% di peso e a risparmiare il 15% sui costi rispetto al loro predecessore Le parti leggere sono state applicate e applicate con successo alle nuove auto del 2021. Il nuovo modello, che dovrebbe essere messo in vendita nella seconda metà di quest'anno, è riuscito a ridurre il peso corporeo con un componente leggero sullo schienale della poltrona della terza fila. La terza fila posteriore della precedente generazione di auto era costituita da 15 diversi componenti in acciaio e la carrozzeria era molto pesante. Quindi si spera che i sedili della terza fila del 2021 soddisfino tutti i criteri di prestazione pur essendo più leggeri e più competitivi in termini di costi. "Essere più leggeri non significa necessariamente essere più costosi", hanno detto i ricercatori. Rispetto al modello della generazione precedente, durante la ricerca e lo sviluppo del nuovo modello, non solo abbiamo ottenuto una riduzione del 30% del peso del sedile della terza fila, ma abbiamo anche risparmiato il 15% del costo. Questi obiettivi vengono raggiunti perché abbiamo molti ottimi partner". Le parti in resina dei seggiolini auto tradizionali contengono rinforzi metallici, che aumentano il costo del processo. La speranza è di ottenere un'intera iniezione di parti senza elaborazioni complesse e costose. Per soddisfare i requisiti, è stato utilizzato un esclusivo prodotto PA6 in poliammide modificato resistente agli urti e rinforzato con fibra di vetro al 35%, insieme al suo strumento proprietario di simulazione al computer (CAE) che può essere utilizzato in più fasi di sviluppo. Gli strumenti proprietari di simulazione al computer (CAE) di Basf "Classifico il design dei sedili della terza fila della Toyota Senna 2021 come una tecnologia abilitante", ha affermato lo sviluppatore. È il primo schienale del suo genere interamente stampato a iniezione ad essere progettato senza inserti e una delle sfide progettuali era garantire che il sedile avesse un elevato allungamento e resistenza agli urti per soddisfare i requisiti di prevenzione degli urti. "Allo stesso tempo, ci siamo concentrati sulla robustezza e sulla rigidità dei sedili, perché anche la terza fila sostiene il pavimento". Contattaci, ti offriremo i migliori materiali al miglior prezzo.

Nylon 12 (PA12) is a kind of polyamide engineering plastics with excellent properties. With rich petroleum by-product butadiene as the main raw material, low production cost, high economic effect, has been widely used in various fields. Modified nylon 12 is made of nylon 12 resin and quantitative filler, color powder, additives and other components blend, after extrusion, granulation and other processes to obtain a thermoplastic with different properties. LFT-G Chemical modified nylon 12 series products are suitable for extrusion, injection molding and other processing technology, can meet the diversified and customized needs of customers, suitable for automobile, electronic appliances, communications, electric power, medical, sports equipment and other fields. Product line includes: Long glass fiber reinforced PA12, Long carbon fiber reinforced PA12 Long glass fiber reinforced PA12 series LFT-G® long glass fiber reinforced PA12 series is divided into LGF20, LGF30, LGF40 and other specifications according to the long glass fiber filling volume, with the long glass fiber content ranging from 20%-60%. Applications: electronic appliances, sports equipment, quick connector, connector, sanitary ware, shell, bracket, etc. Long carbon fiber reinforced PA12 series La serie PA12 rinforzata con fibra di carbonio lunga LFT-G® è suddivisa nelle specifiche LCF30, LCF40, LCF50 in base alla quantità di riempimento della fibra di carbonio (20% -60%). Ha una buona resistenza, stabilità dimensionale, conducibilità, resistenza agli urti, ecc. Applicazioni: apparecchi elettronici, attrezzature sportive, connettore rapido, connettore, sanitari, scocca, staffa, ecc. Per noi sono disponibili anche altri PA12 funzionali come il grado resistente Toughten, il grado resistente ai raggi UV, ecc.

Sales of new energy vehicles increased significantly Make the concept of "car lightweight" It's hot again. A variety of modified plastics, composite materials and light alloy materials are increasingly mature, not only in the traditional automobile engine around, but also in the power battery of new energy vehicles, there are a variety of plastic applications. But these plastics do not perform well on the safety issue of flame retardancy. Flame retardant and its related industries along with "automobile lightweight" become the hot spot of the automobile industry. Development direction of flame retardant plastics for auto parts At present, the common types of flame retardant materials used in automotive parts are PP, PA, PU, PC, ABS materials, as well as a variety of modified materials and composite materials composed of them. Compared with traditional fuel vehicles, new energy vehicles have added battery modules, charging piles and charging guns and other components. ➡️ The amount of engineering plastics used for battery pack module of a single new energy vehicle is about 30kg. The plastic shell of new energy vehicle mainly uses modified PP, modified PPS, PPO and other high temperature resistant plastics. ➡️ Charging piles require engineering plastics due to high usage standards and harsh operating environment. Each charging pile needs about 6kg engineering plastics. At present, PBT, PA and PC are commonly used. When preparing flame retardant plastics, most of them will increase their limiting oxygen index LOI to about 25-35%, so as to effectively improve the overall safety index of vehicles. In addition, with the current combination of electrification and carbon neutrality, plastics and various flame retardants containing halogens will be more restricted. Therefore, the future development direction of flame retardant plastics, in addition to the need for sufficient mechanical properties to meet the lightweight demand, in electric vehicles and other fields will also need materials to pay attention to the electrical, processing, environmental protection requirements Flame retardants will develop towards the direction of halogen-free and high performance, while the research focus of high performance flame retardants will develop towards the direction of complex co-effect flame retardants, halogen-free flame retardants, expansion flame retardants, superrefinement, nano technology, high efficiency surface chemical modification technology and multi-functional technology. Application of flame retardant materials in automobile parts At present, the flame-retardant plastics mainly used are PP, PU, ABS and PC. According to the special needs of automobile parts, composites (alloying), PA, PBT and PMMA are also used accordingly. Flame retardant PP PP is the largest amount of automotive plastic polymer material, has excellent chemical corrosion resistance, and the processing process is simple, low cost. Widely used in automobile instrument panel, battery pac...

Long Glass Fiber reinforced polypropylene plastic refers to the modified polypropylene composite material which contains the glass fiber length between 10 and 25mm. After injection molding and other processes, the three-dimensional structure is formed. It is also called Long Glass Fiber polypropylene, or LGFPP. There are also many materials at home and abroad referred to Long fiber reinforced thermoplastic as LFT, that is, the abbreviation of long-fiber reinforce thermoplastic. From the material definition, LGFPP belongs to a kind of LFT. Material characteristics Microstructure determines macro performance, so 10~25mm long glass fiber reinforced plastics (LGFPP) compared with ordinary 4~7mm short glass fiber reinforced plastics (GFPP) has higher strength, stiffness, toughness, dimensional stability, low warpage. In addition, long glass fiber reinforced polypropylene has better creep resistance than short glass fiber reinforced polypropylene even if it is subjected to 100℃. On the injection molding product, the long glass fiber interleaved into a three-dimensional network structure, even after the polypropylene substrate is burned, the long glass fiber network still forms a certain strength of the glass fiber skeleton, while the short glass fiber after burning generally into a non-strength fiber skeleton. This is mainly because the ratio of length to diameter of reinforced fiber determines the reinforcement effect. The critical length to diameter ratio is L/D. The packing and short glass fiber with the critical length to diameter ratio less than 100 have no reinforcement effect, while the long glass fiber with the critical length to diameter ratio less than 100 has the reinforcement effect. Compared with metal materials and thermosetting composites, the density of long glass fiber plastics is low, and the weight of the same parts can be reduced by 20~50%. Long glass fiber plastics can provide designers with greater design flexibility, such as forming parts with complex shapes, integrating the number of parts used, saving the cost of the mold (generally the cost of long glass fiber plastic injection mold is about 20% of the cost of metal stamping mold). Reduce energy consumption (production energy consumption of long glass fiber plastics is only 60~80% of steel products, 35~50% of aluminum products), simplify the assembly process. What are the typical application parts of automobile Based on the application advantages of long glass fiber material, it has been applied more and more widely in automobiles. In the mainstream models and new models, we have seen more and more of the following parts are made of long glass fiber reinforced polypropylene material. Long fiber reinforced polypropylene is used in car dashboard body frame, battery bracket, front end module, control box, seat support frame, spare placenta, fender, chassis cover plate, noise partition, rear door frame, etc. The following, a few long glass fiber plastic typical application parts a...

Il team di lft-g® ha una conoscenza combinata di 20 anni di materiali compositi, i nostri progettisti, materiali e ingegneri di processo sono sempre disponibili a rispondere alle vostre domande e il nostro partner sarà lì per supportarvi durante l'intero ciclo di vita del prodotto.

condividere con voi alcuni dei nuovi prodotti di sviluppo della nostra fabbrica, partecipazione a forum di settore, formazione, mostre e condivisione con esempi di forum di alto livello sponsorizzati dall'industria.

2026

Xiamen LFT Composite Plastics 2026 Spring Commencement Ceremony As the spring breeze brings warmth and all things come back to life, the team of Xiamen LFT Composite Plastics Co., Ltd. gathered with excitement to welcome the first working day of 2026. Let’s relive this vibrant and hopeful New Year kickoff moment together! From the warmth of lucky red envelopes at the entrance to the excitement of the scratch-off games, every moment was filled with New Year joy and strong team spirit. This was more than just a back-to-work ceremony — it was a vivid reflection of our unity, shared vision, and confidence as we move boldly into 2026. PART 01 Lucky Red Envelopes – A Prosperous Start Early in the morning, the management team gathered in the lobby to personally welcome each returning colleague with a New Year red envelope. More than a thoughtful gesture, it carried heartfelt blessings for the year ahead — symbolizing prosperity, success, and continuous good fortune for every member of the LFT family. Prosperous start to work! Wishing everyone a smooth year, great success, and abundant good luck! PART 02 Scratch-Off Game – Surprises & Smiles Following the red envelope ceremony, the exciting scratch-off game began. Each participant had the opportunity to win New Year surprises, filling the venue with laughter, anticipation, and cheerful energy. Beyond the fun and prizes, the activity strengthened our team spirit. In a joyful and relaxed atmosphere, everyone felt the warmth of togetherness — injecting fresh motivation and positivity into the year ahead. PART 03 Full of Energy, Ready for 2026 The LFT team returned with enthusiasm, confident smiles, and determined expressions. This vibrant energy is one of our greatest strengths. The laughter and group photos perfectly captured the unity and forward-looking spirit of our team as we stride confidently into the new year. A New Year. A New Journey. A Stronger Future. With passion, professionalism, and teamwork, Xiamen LFT Composite Plastics is ready to create greater value for our global partners in 2026.

leggi di più2026

Galloping horses bid farewell to the old year, and the spirited Dragon-Horse energy welcomes the New Year! In this Year of the Horse, all colleagues at Xiamen LFT Composite Plastics Co., Ltd. extend our most sincere New Year wishes to every hardworking employee and their families. May the new year bring you the strength to ride forward with confidence, reach new heights, and achieve success in all that you pursue! PART 01 Horse Spirit | New Year Greetings PART 02 New Year Gift Packages The New Year gift distribution was lively and bustling, with employees queuing in an orderly manner, their faces beaming with happiness. Each gift package includes a box of oranges, a bag of rice, a box of tea, and a bottle of cooking oil—every item carrying the company’s heartfelt blessings for its employees. The scene was filled with laughter and cheer as employees exchanged greetings and shared the joy of the New Year. Boxes of fresh oranges, bags of premium rice, boxes of fragrant tea, and barrels of high-quality cooking oil were more than just gifts—they embodied the company’s recognition and gratitude for the employees’ hard work and dedication. PART 03 Thoughtful Gifts, Deep Affection Xiamen LFT Composite Plastics always adheres to the corporate culture of “People-Oriented, Co-Creation and Sharing”, placing employees’ well-being at the forefront. The New Year benefits are more than just gifts—they reflect the company’s commitment to growing together with its employees and sharing the fruits of success. Oranges: symbolize wishes coming true, hoping every employee achieves their dreams in the new year. Rice: represents abundance, wishing everyone a prosperous life with no worries about food or clothing. Tea: stands for elegance and serenity, hoping employees can enjoy moments of calm amid their busy days. Cooking Oil: signifies a thriving life, wishing everyone’s days to flourish and prosper. PART 04 Employee Reflections | Year of the Horse Outlook “Receiving the company’s New Year gift package warms my heart! All four items are very practical, and they not only show the company’s care but also fill me with excitement for the Year of the Horse. I hope the company gallops forward like a spirited horse in the new year, and that we can grow together with it!” — Mr. Wu, Foreign Trade Department “Oranges, rice, tea, and oil—each represents the company’s heartfelt wishes. With the Year of the Horse here, I wish the company great success and continuously rising achievements! I also hope that every employee can embrace the Dragon-Horse spirit and achieve even greater results!” — Engineer Zhang, R&D Department “Having worked at Xiamen LFT Composite Plastics for several years, I deeply feel the company’s human-centered care. The New Year gift package may not be extravagant, but the thought behind it is truly touching. In the new year, I will work even harder to contribute to the company’s development!” — Ms. Li, Ex

leggi di più2026