-

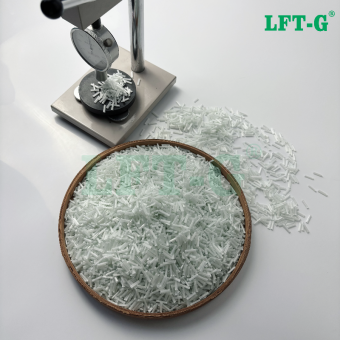

LFT-G Riempimento in poliammide 6 nylon 6 fibra di vetro lunga colore originale per parti automobilisticheI principali vantaggi di nylon 6 sono i suoi rigidità E resistenza all'abrasione Inoltre, questo materiale ha eccellente resistenza agli urti , resistenza all'usura , E proprietà isolanti elettriche Il nylon 6 è un altamente elastico E materiale resistente alla fatica , il che significa che tornerà alle sue proporzioni originali dopo essere stato deformato dalla tensione. Questa poliammide è atossica e può essere combinata con fibre di vetro o carbonio per aumentarne le prestazioni.

- Proprietà composite della poliammide 6

- resina termoplastica lgf buon prezzo

- PA6 ad alto impatto invece di plastica metallica

- filtro in plastica per stampaggio a iniezione gf30

- riempimento in pa6 fibra di vetro lunga personalizzata

- Composti leggeri in plastica rinforzata

Tag :

-

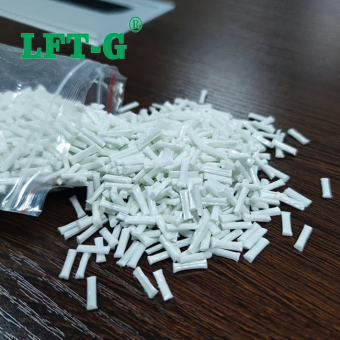

Pellet rinforzati in nylon PA6 fibra di carbonioNylon 6 è un materiale adatto per stampaggio a iniezione I pezzi stampati in nylon risultanti possiedono un'elevata resistenza, nonché resistenza chimica e termica. Durante lo stampaggio del nylon 6, il materiale viene talvolta iniettato con una quantità specifica di fibre di vetro o di carbonio (di solito tra 20% e 60% ) per aumentarne la resistenza alla trazione.

- composto lucidante per fibra di carbonio

- pellet di carbonio

- poliammide nylon 6

- densità poliammidica 6

- nylon 6 poliammide

- pellet di carbone attivo

Tag :

-

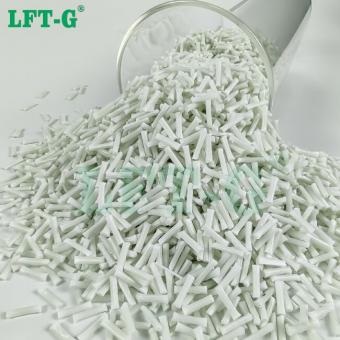

LFT-G PA6 Poliammide6 nylon6 riempimento fibra di vetro lunga40 colore originale per parti automobilisticheNylon rinforzato con fibra di vetro lunga PA6 e PA6-LGF PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificates

- Composito di poliammide 6

- resina termoplastica lgf

- PA6 ad alto impatto

- stampaggio a iniezione di plastica

- riempimento in pa6 fibra di vetro lunga

- Plastica rinforzata

Tag :

-

Composti in fibra di carbonio lunga riempiti con resina termoplastica LFT-G Nylon 6,6Il materiale Nylon 66 per lavorazioni meccaniche presenta una migliore resistenza alla temperatura e minori tassi di assorbimento dell'acqua rispetto al nylon 6 standard.

- Compositi in fibra di carbonio PA66

- Materiali strutturali leggeri

- Poliammide 66 ad alta resistenza

- Compositi in fibra di carbonio per l'industria automobilistica

- Resistenza del nylon rinforzato con fibra di carbonio

- Compositi termoplastici avanzati

Tag :

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文