-

LFT-G PPS Polifenilensolfuro composito resina termoplastica fibra di carbonio lunga colore originale 12mmPPS Special engineering plastics are engineering plastics with higher overall performance and long-term use temperature above 150℃, PPS is one of them. The carbon fiber reinforced special engineering composites formed by carbon fiber as the reinforcement and these special engineering plastics as the matrix have excellent mechanical properties, wear resistance and high temperature resistance, which can be used in aerospace, marine or medical fields, and in some aspects show more desirable application advantages than thermosetting resins or even metal materials. PPS-LCF Polyphenylene sulfide PPS resin strength and hardness are relatively high, good mechanical properties, adapt to a variety of molding and processing methods, you can achieve secondary precision molding, the dimensional stability of the product is better. Its moisture absorption rate of only 0.03%, low density, melt temperature Tm of 285 ℃, the glass transition temperature Tg of 90 ℃, thermal stability is very good, in the air state, to reach 430 ℃ -460 ℃ before decomposition, high flame retardant grade, 200 ℃ insoluble in most organic solvents, excellent electrical insulation. As a special engineering plastics, PPS advantages are outstanding, but defects also exist, for example, because of the large number of benzene ring to make its impact resistance and elongation is not good enough, but through the carbon fiber reinforced way, can further improve the performance of the material strength and thermal stability, so as to better show the value of the application of the material. Through the carbon fiber reinforced intervention, changing the original insulating properties of PPS into a conductive, anti-static properties, polyphenylene sulfide PPS toughness and strength can be substantially increased and improved, becoming one of the most commonly used composite materials in the aerospace field. It is used in aircraft landing gear, wings, hatches, fuel tank port covers, J-shaped nose cone, cabin interior trim and other components, not only to help increase the impact resistance, high temperature and corrosion resistance of these parts, more through the reduction in mass, to enhance the aircraft load efficiency and reduce fuel consumption. Compared with metal, this composite material has the advantages of low cost and easy processing, the cost can be reduced by 20-50 percent. High bonding must be maintained between the carbon fiber reinforcement and the PPS resin matrix. When the product is subjected to stress, this high bonding helps the interface to transfer the external load to the fibers effectively, which can effectively prevent cracks from debonding between the interfaces, in addition to enhancing the mechanical properties of the composite. To make the resin matrix and carbon fiber reinforcement between the formation of high bonding, we must make the molten state of PPS resin and carbon fiber reinforcement in full contact, full impregnation, so that the fiber body in the case of uniform dispersion to achieve good impregnation effect. Production process Application of PPS-LCF Xiamen LFT composite plastic Co., Ltd We will offer you: 1. LFT & LFRT material technical parameters and leading edge design 2. Progettazione e raccomandazioni del frontale dello stampo 3. Fornire supporto tecnico come lo stampaggio ad iniezione e lo stampaggio per estrusione. Chi siamo

- PPS polifenilente

- Apparecchio elettronico a bassa deformazione

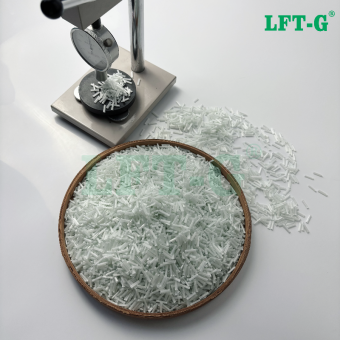

- pps lcf40 granuli materia prima

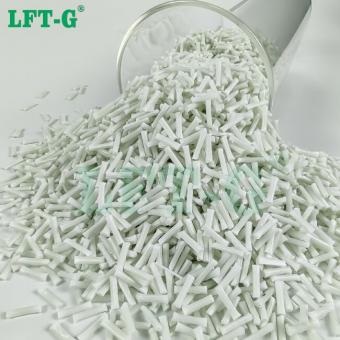

- PPS lunga estrusione in fibra di carbonio

- pps LCf40 parte di iniezione plastica

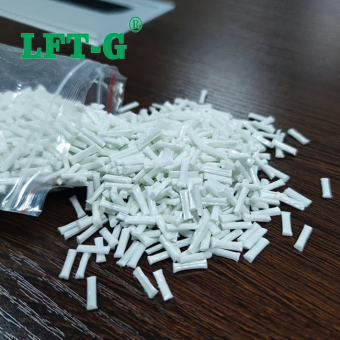

- Pellet in fibra di carbonio polimerica PPS

Tag :

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文