-

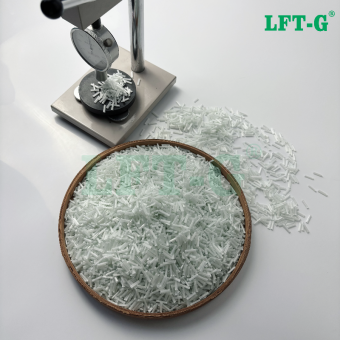

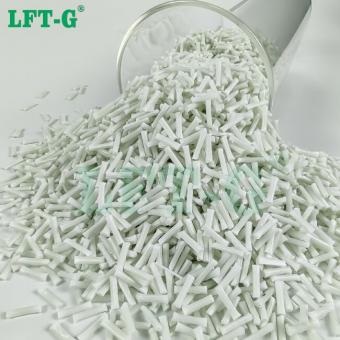

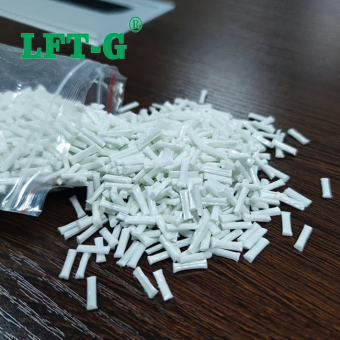

Xiamen lft Poliammide6 plastica rinforzata con fibra di vetro lunga ad alta tenacità leggera 12 mmRiempimento PA66 LGF Il nylon (PA) ha una serie di proprietà eccellenti, come elevata resistenza meccanica, resistenza chimica, resistenza all'olio, resistenza all'usura, autolubrificazione, facilità di lavorazione e formatura, ed è diventato uno dei tecnopolimeri termoplastici ampiamente utilizzati in patria e all'estero . Ma nell'applicazione pratica, i requisiti prestazionali del nylon sono diversi in condizioni o ambienti diversi. Ad esempio, il trapano elettrico e l'involucro del motore, la girante della pompa, il cuscinetto, il motore diesel e la ventola dell'aria condizionata e altre parti richiedono che il materiale in nylon abbia un'elevata resistenza, un'elevata rigidità e un'elevata stabilità dimensionale; A causa della scarsa tenacità del nylon a bassa temperatura, è necessario temprarlo. In alcune applicazioni all'aperto, i materiali in nylon devono essere resistenti alle intemperie in ambienti esterni a lungo termine. I materiali rinforzati utilizzati per il nylon sono principalmente fibra di vetro, fibra di carbonio, baffi e altri materiali fibrosi, e la fibra di vetro rinforzata è la più utilizzata. Il rinforzo in fibra di vetro può ovviamente migliorare la resistenza alla rigidità e la durezza del materiale, e la stabilità dimensionale e la resistenza al calore del materiale sono ovviamente migliorate. Perché il nylon stesso non è abbastanza forte, aggiungendo dal 10 al 30 percento della fibra, per aumentarne la resistenza. In particolare, il 30% di forza è considerato il rapporto più appropriato. Anche aggiunto al 40-50%, in base alle esigenze specifiche dei diversi prodotti, abbinato alla formula appropriata, può avere successo. Tecnologia di produzione del nylon rinforzato con fibra di vetro Long fiber method, that is, nylon and other components are premixed and added to the hopper, and the glass fiber from the glass fiber entrance through the screw rotation into the screw, and then mixed with nylon resin. Factors affecting the properties of glass fiber reinforced nylon Firstly, the interface bond between glass fiber and nylon resin has the most important effect on glass fiber reinforced nylon. If the combination between the two is not good, the reinforcement effect will be greatly reduced. At this time, the surface treatment of glass fiber is particularly important. Today, fiberglass manufacturers have been able to produce fiberglass models for different materials with different surface treatments for use by modified plastics manufacturers, as long as the right choice. Second, the length of glass fiber in nylon material is another major factor affecting its properties. In general, long glass fibers are superior to short glass fibers in terms of tensile strength, bending strength and modulus, and notched impact strength. At the same time, the dispersion of glass fiber in the material can not be ignored. The dispersion of glass fiber mainly depends on the appropriate shearing action of twin-screw and the kneading action of material, which involves the combination and speed of screw. The selection of screw speed is related to the content of additives such as glass fiber in the formula. For flame-retardant reinforced nylon, low speed is appropriate because the flame retardant has been decomposed by heat. In addition, processing temperature, glass fiber diameter, glass fiber type will also affect the final performance of the material, so it will not be repeated here. Glass fiber enhances the fluidity of nylon The fluidity of glass fiber reinforced nylon is poor, and problems such as high injection pressure, high injection temperature, dissatisfaction with injection molding and poor surface quality are easy to occur in the process of injection molding, which seriously affect the appearance of products and lead to a high defect rate of products. Especially in the production process of injection molding products, and can not directly add lubricant to solve the problem, can only be improved on the raw material, generally speaking, this needs to be added in the modified formula lubrication componentS. Resistance of glass fiber reinforced nylon to high temperature heat and oxygen aging In some applications such as bearings and diesel fans, glass fiber reinforced nylon often faces the problem of long time high temperature thermal and oxygen aging. Although the reinforced modification of nylon with glass fiber can moderately improve the heat resistance of nylon, it can not solve the problem well. Better results can be achieved by adding appropriate anti-thermal oxygen aging additives to the glass fiber reinforced nylon composite material, as shown in the figure above. Glass fiber enhances the weather resistance of nylon Nylon under the influence of sunlight, temperature change, wind and rain and other external conditions, there will be a series of aging phenomena such as fading, discoloration, cracking, powder and strength reduction, among which UV is the key factor to promote aging. Weather resista...

- plastica di nylon pa66

- Poliammide66 fibra di vetro lunga

- pa66 riempire gf

- materia prima plastica pa66

- materiali compositi pa66

- resina termoplastica

Tag :

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文