-

Riempimento Xiamen LFT MXD6 Campione di colore naturale per stampaggio ad iniezione ad alta tenacità in fibra di vetro lunga 30 disponibileMXD6 Polyadipyl-m-benzoylamine, referred to as mxd6, generally referred to as "nylon mxd6", resin than other engineering plastics have higher mechanical strength and modulus, is also a special high barrier nylon material. Although the barrier of mxd6 is slightly worse than that of pvdc and evoh, its barrier is not affected by temperature and humidity, which is especially suitable for high temperature and humid occasions. In today's barrier packaging and plastic instead of steel general trend, nylon mxd6 has become one of the most eye-catching new plastic varieties. Structure performance: PA MXD6 nylon material has high strength, high rigidity, high thermal deformation temperature, small thermal expansion coefficient; Dimensional stability, low water absorption rate and small size change after water absorption, mechanical strength changes less; Forming shrinkage is small, suitable for precision forming processing; Excellent coating performance, especially suitable for high temperature surface coating; Excellent barrier to oxygen, carbon dioxide and other gases. Excellent mechanical and thermal properties and high strength, high modulus and heat resistance, high barrier, excellent cooking resistance Advantages 1、Maintain high strength and rigidity in a wide temperature range 2、High heat deflection temperature, small coefficient of thermal expansion 3、Low water absorption, small size change after water absorption, less mechanical strength reduction 4、Small shrinkage rate of molding, suitable for precision molding process 5、Excellent paintability, especially suitable for surface painting under high temperature 6、Excellent barrier to oxygen, carbon dioxide and other gases MXD6-LGF MXD6 applications in the plastics modification industry MXD6 can be compounded with glass fibers, carbon fibers, minerals and/or advanced fillers for materials containing 50-60% glass fiber reinforcement with exceptional strength and stiffness. Even when filled with high levels of glass fiber, its smooth, resin-rich surface creates a high gloss finish like no glass fiber, making it ideal for painting, metal coating or creating naturally reflective housings. 1、High fluidity for thin wall It is a very high flowing resin that can easily fill thin walls as thin as 0.5 mm thick even with glass fiber content as high as 60%. 2、Excellent surface finish The resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content. 3、Very high strength and stiffness MXD6 with 50-60% glass fiber reinforcement has a tensile and flexural strength similar to many cast metals and alloys. 4、Good dimensional stability At ambient temperature, the coefficient of linear expansion (CLTE) of MXD6 glass fiber composite is similar to that of many cast metals and alloys. It is highly reproducible due to low shrinkage and the ability to maintain tight tolerances (length tolerances can be as low as ± 0.05% if properly formed). TDS for reference only Application MXD6 replaces metal to make high quality structural parts for automobiles, electronics and electrical appliances Nelle parti automobilistiche, molte occasioni richiedono prodotti materiali con elevata resistenza meccanica e buona resistenza all'olio e possono essere utilizzati a lungo nell'intervallo 120-160 ℃. L'MXD6 rinforzato con fibra di vetro ha una resistenza al calore fino a 225 ℃ e un tasso di ritenzione ad alta resistenza ad alta temperatura, che può essere utilizzato per blocco cilindri, testata, pistone, ingranaggio sincrono di motori di automobili, ecc. La lega MXD6/PPO ha le proprietà di resistenza alle alte temperature, elevata resistenza, resistenza all'olio, resistenza all'usura, buona stabilità dimensionale, ecc. Può essere utilizzato per pannelli esterni verticali di carrozzerie automobilistiche, parafanghi anteriori e posteriori, copriruota e quasi impossibile da stampare e formare da Lamiera d'acciaio. parti curve e telai di automobili. Chi siamo

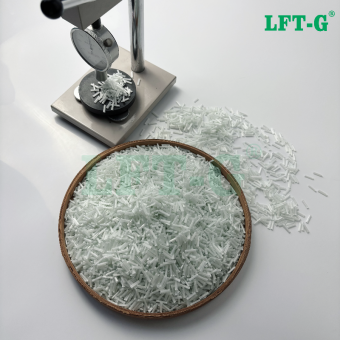

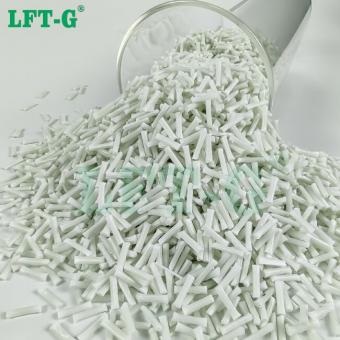

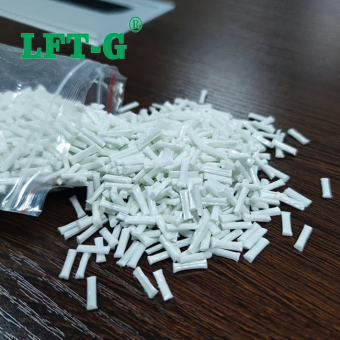

- fibra di vetro lunga MXD6

- termoplastici rinforzati con fibre lunghe

- granuli lunghi di plastica rinforzata con fibra di vetro

- MXD6 LGF

- granuli di plastica rinforzata con fibra di vetro

- Composti MXD6

Tag :

-

LFT-G ABS Acrilonitrile Butadiene Stirene riempimento fibra di vetro lunga ad alte prestazioni per uso industrialeaddominali La resina ABS è un materiale strutturale polimerico termoplastico con elevata resistenza, buona tenacità e facilità di lavorazione e stampaggio. Granuli lunghi di ABS rinforzati con fibra di vetro La plastica rinforzata con fibra di vetro lunga si basa sulla plastica pura originale, aggiungendo fibra di vetro lunga e altri additivi, in modo da migliorare l'ambito di utilizzo del materiale. In generale, la maggior parte dei materiali rinforzati con fibra di vetro lunga sono utilizzati principalmente nelle parti strutturali dei prodotti, che è un materiale di ingegneria strutturale, come PP, ABS, PA66, PA6, PBT, PPS, ecc. Vantaggi Dopo la fibra di vetro lunga rinforzata , la fibra di vetro lunga è un materiale resistente alle alte temperature, pertanto la temperatura di resistenza al calore della plastica rinforzata è molto più alta rispetto a prima senza fibra di vetro lunga. After long glass fiber reinforced, the addition of long glass fiber restricts the movement of polymer chains between plastics, so the shrinkage of reinforced plastics is much lower and the rigidity is much higher. After long glass fiber reinforcement, the reinforced plastic will not be stress cracked, and the impact resistance of the plastic will be improved. After long glass fiber reinforcement, long glass fiber is a high-strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, much higher. After the long glass fiber reinforcement, the burning performance of the reinforced plastic decreases a lot due to the addition of long glass fiber and other additives, and most of the materials cannot be ignited, which is a kind of flame retardant material. Datasheet for reference Application Can be used at many fields. For more details, please contact us. Other products you may wonder PP-NA-LGF PA6-NA-LGF TPU-NA-LGF Frequently asked questions Q. What are the differences and advantages of long fiber materials and thermosets and staple fibers? A. Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher toughness than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Compared with thermosets, it is more environmentally friendly. It can be recycled and reused, and has simple molding efficiency, lower cost etc. But its mechanical properties are worse than thermosets. Q. Using a long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not? A. When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itsalf has requirements for the mold nozzle. Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material? A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is reinforced and how much length is more appropreate, which are depending on the performance requirements of the products. Xiamen LFT composite plastic Co., Ltd. We will offer you 1. LFT & LFRT material technical parameters and leading edge design 2. Mold front design and recommendations 3. Provide technical support such as injection molding and extrusion molding

- fibra di vetro lunga ABS

- mescole a fibra lunga ABS

- granuli di ABS composito a fibra lunga

- ABS sinistro

Tag :

-

Riempimento MXD6 Fibra di vetro lunga 30 ad alta tenacità stampaggio a iniezione campione di colore naturale disponibilePlastica MXD6 | MXD6 rinforzato con fibre di vetro lunghe (MXD6-LGF) Che cos'è MXD6? Poliadil-m-benzoilammina, comunemente chiamata MXD6 O nylon MXD6 , è un termoplastico ingegneristico ad alte prestazioni. Rispetto ad altri materiali plastici ingegneristici, MXD6 ha una maggiore resistenza meccanica e un modulo elastico più elevato. È anche uno speciale nylon ad alta barriera, con un'eccellente resistenza all'ossigeno e all'anidride carbonica. A differenza del PVDC o dell'EVOH, le sue prestazioni di barriera non sono influenzate dalla temperatura o dall'umidità, rendendo MXD6 ideale per condizioni di alta temperatura e umidità. Prestazioni strutturali e meccaniche Il nylon MXD6 presenta elevata resistenza, elevata rigidità, elevata temperatura di deformazione termica, bassa dilatazione termica, eccellente stabilità dimensionale e basso assorbimento d'acqua. Le sue proprietà meccaniche variano minimamente dopo l'assorbimento d'acqua. MXD6 presenta un basso ritiro per la formatura di precisione, un'eccellente verniciabilità ad alte temperature e straordinarie proprietà barriera. Vantaggi di MXD6 Mantiene elevata resistenza e rigidità in un ampio intervallo di temperature Elevata temperatura di deflessione del calore con basso coefficiente di dilatazione termica Basso assorbimento d'acqua e minima riduzione delle proprietà meccaniche Ritiro di stampaggio ridotto, adatto per processi di stampaggio di precisione Ottima verniciabilità, soprattutto ad alte temperature Barriera eccezionale all'ossigeno, all'anidride carbonica e ad altri gas MXD6-LGF | MXD6 rinforzato con fibra di vetro lunga L'MXD6 può essere miscelato con fibre di vetro lunghe, fibre di carbonio, minerali e riempitivi avanzati per produrre compositi con rinforzo in fibra di vetro al 50-60%. Ciò si traduce in eccezionale resistenza e rigidità, pur mantenendo una superficie liscia e ricca di resina, ideale per verniciatura, rivestimento metallico o alloggiamenti riflettenti. Vantaggi principali di MXD6-LGF Elevata fluidità per pareti sottili: Può riempire pareti sottili fino a 0,5 mm anche con il 60% di contenuto di fibra di vetro. Ottima finitura superficiale: Le superfici ricche di resina garantiscono un aspetto molto lucido nonostante l'elevato contenuto di fibre. Elevatissima resistenza e rigidità: Paragonabile a molti metalli fusi e leghe con il 50-60% di fibra di vetro. Buona stabilità dimensionale: Basso ritiro e tolleranze ristrette; coefficiente di dilatazione lineare simile a quello di molti metalli. MXD6-LGF TDS (Scheda tecnica) Applicazioni di MXD6-LGF MXD6-LGF Sostituisce i metalli per componenti strutturali di alta qualità nei settori automobilistico, elettronico ed elettrico. Offre ottime prestazioni in ambienti che richiedono elevata resistenza meccanica e resistenza agli oli, operando a lungo termine a temperature comprese tra 120 e 160 °C. Grazie al rinforzo in fibra di vetro, MXD6 mantiene una resistenza al calore fino a 225 °C, ideale per blocchi cilindri, testate, pistoni e ingranaggi sincroni dei motori automobilistici. Le leghe MXD6/PPO offrono resistenza alle alte temperature, elevata resistenza, resistenza all'usura, resistenza all'olio ed eccellente stabilità dimensionale, consentendo la sostituzione del metallo nei pannelli della carrozzeria, nei parafanghi, nei copricerchi e nelle parti curve complesse delle automobili. Chi siamovedere di più

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文