-

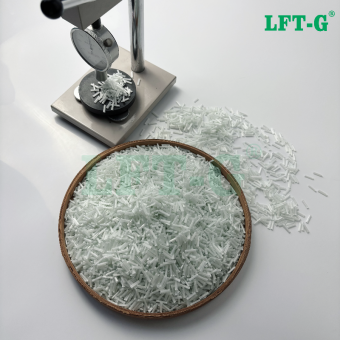

Nuovi materiali LGF Poliammide 66 Nylon per applicazioni strutturaliNostro Materiale rinforzato con fibra di vetro lunga PA66 è un composito termoplastico ad alte prestazioni sviluppato per applicazioni che richiedono resistenza meccanica superiore, stabilità dimensionale e resistenza al calore. Ideale per sostituzione del metallo e componenti strutturali ad alto carico.

- nylon pa66 gf30

- fornitore cinese pa 66

- compositi a fibra lunga

- prezzo gfrp al kg

- ingegnere nylon

- stampaggio a iniezione di nylon

Tag :

-

Composti ABS modificati LFT-G in fibra di vetro lunga per componenti automobilisticiLo stampaggio a iniezione ABS si riferisce al processo di iniezione di materiale fuso plastica ABS in uno stampo ad alte pressioni e temperature. Esistono molti ABS applicazioni di stampaggio a iniezione poiché è una plastica ampiamente utilizzata e può essere trovata nel industrie automobilistica, dei beni di consumo e delle costruzioni per citarne alcuni.

- ABS polimero rinforzato con fibra di vetro lunga

- ABS rinforzato con fibre lunghe

- stampo a iniezione lgf abs per ingegneria

- Produttore cinese ABS GF rinforzato con fibra

- Composito plastico ABS ad alte prestazioni

- Materiali ABS di colore naturale con riempitivo

Tag :

-

Composti LFT PLA resina termoplastica a fibra di vetro lungaIl PLA (acido polilattico) è un poliestere termoplastico semicristallino. È derivato da fonti rinnovabili ed è quindi classificata come bioplastica.

- Fabbrica di fibra di vetro PLA Long

- Stampaggio a iniezione di plastica speciale PLA

- polimero plastico rinforzato con fibre

- Buona resistenza del produttore PLA

- Plastica speciale per ingegneria

- Pellet di PLA puro grado vergine lft

Tag :

-

LFT-G nylon66 modificato PA66 riempimento composti di fibre di vetro lunghe apparecchi elettroniciNylon rinforzato con fibra di vetro lunga PA66-LGF PA66, or Nylon 66, is a high-performance polyamide widely used in engineering plastics. It offers excellent mechanical properties including tensile strength, flexural strength, and impact resistance, along with superior thermal and chemical stability. With lightweight, high wear resistance, good electrical insulation, and self-extinguishing properties, PA66 is ideal for automotive, electrical, industrial equipment, and construction applications. Why Reinforce PA66 with Long Glass Fiber? While PA66 is versatile, it has limitations: high water absorption, low compressive strength when wet, poor alkali resistance, and potential deformation at ultra-low temperatures. Long glass fiber (LGF) reinforcement addresses these challenges. Adding LGF significantly improves impact resistance, thermal deformation resistance, mechanical performance, molding processability, and chemical resistance. LGF acts as a robust internal skeleton, enhancing the durability and reliability of PA66 components. PA66-LGF Technical Datasheet *The datasheet is tested by Xiamen LFT and provided for reference only.* Applications of PA66-LGF PA66 reinforced with 30% long glass fiber is ideal for high-performance applications such as: Automotive components and structural parts Power tool housings and mechanical parts Industrial equipment components For specialized applications, please consult our technical team. PA66-LGF Product Details Number Color Length Sample MOQ Port of Loading Delivery Time Payment Terms PA66-NA-LGF30 Original color (customizable) 12mm (customizable) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT Composite Plastic Co., Ltd Xiamen LFT Composite Plastic Co., Ltd. is a leading manufacturer specializing in long fiber reinforced thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT can be applied in LFT-G injection molding, extrusion molding, and LFT-D molding. We provide products according to customer requirements with fiber lengths from 5 to 25mm. Our continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 certifications and hold numerous national patents and trademarks. Our Services Technical parameters and leading-edge design of LFT & LFRT materials Mold front design recommendations Technical support for injection molding and extrusion molding processes

- Apparecchio elettronico a bassa deformazione

- pellet PA66 autoalimentati

- pellet PA66 rinforzati ad alta resistenza e tenacità

- i migliori granuli di fibra di vetro lunga pa66 lgf30

- PA66 6 pellet lgf a doppia vite

- Applicazione dei granuli di PA66 a fibra lunga

Tag :

-

Composti di acido polilattico PLA Resina termoplastica a fibra di vetro lunga per l'ingegneriaPLA e LGFPLA – Bioplastiche ecologiche e rinforzate PLA (Polylactic Acid) is a non-natural polyester and one of the most promising "green plastics." Known for its biocompatibility, biodegradability, and high mechanical strength, PLA can be completely degraded by microorganisms into CO₂ and water, making it non-toxic and environmentally friendly. PLA offers mechanical properties similar to polypropylene, while providing the gloss, clarity, and processability of polystyrene. With a lower processing temperature than polyolefins, PLA can be molded via injection molding, extrusion, blow molding, spinning, and other general plastic processes. Its applications range from disposable packaging and fibers to nonwovens, and extend to medical, chemical, pharmaceutical, and 3D printing industries. Long Glass Fiber Reinforced PLA (LGFPLA) Glass fiber is an inorganic non-metallic material with excellent insulation, heat resistance, corrosion resistance, and mechanical strength. When used to reinforce PLA, it creates Long Glass Fiber PLA (LGFPLA), a high-performance thermoplastic composite with glass fibers 10–25mm long, forming a 3D structure for superior strength and stability. LGFPLA is available as columnar pellets, typically 12mm (for injection molding) or 25mm (for compression molding) in length, with glass fiber content from 20% to 60%. Colors can be customized to match client requirements. Advantages of LGF vs SGF (Long Fiber vs Short Fiber PLA) Longer fiber length improves mechanical properties and part durability. High specific stiffness and strength, with excellent impact resistance — ideal for automotive parts. Improved creep resistance and dimensional stability for precise molding. Outstanding fatigue resistance and long-term reliability. Stable performance in high temperature and humid environments. Minimal fiber damage during molding due to fiber mobility within the mold. Technical Specifications Product Number Color Length Fiber Specification Package Sample Port of Loading Delivery Time PLA-NA-LGF Natural or customizable 6–25mm 20%–60% 25kg/bag Available Xiamen Port 7–15 days after shipment Lab & Factory Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in developing and producing long glass fiber (LGF) and long carbon fiber (LCF) reinforced thermoplastic composites (LFT-G, LFRT, LFT). Our materials are lightweight, high-strength, impact-resistant, and environmentally friendly, offering excellent corrosion and chemical resistance along with superior molding performance. Our products are used across industries including automotive, aerospace, military, electrical, medical, sports equipment, and daily consumer goods, producing components such as gears, rollers, pulleys, pump impellers, fan blades, and more.

- PLA plastica rinforzata lgf produzione pla

- Materiali modificati per stampaggio a iniezione LFT-G PLA

- composti di fibre di vetro lunghe resina pla basica

- Pellet di PLA di fibra lunga 30 prodotti in Cina

- Produttore di polimeri PLA auto-adesivi, vendita diretta

Tag :

-

LFT-G Poliammide 12 composti rinforzati con fibre di carbonio lunghe nylon per parti di automobiliFibra di carbonio lunga La fibra di carbonio presenta proprietà eccezionali, tra cui resistenza assiale e modulo elastico estremamente elevati, bassa densità ed eccellenti prestazioni specifiche. Non presenta creep, presenta un'eccellente resistenza alla fatica, un'eccellente resistenza alla corrosione e mantiene la stabilità a temperature molto elevate in ambienti non ossidanti. La fibra di carbonio presenta inoltre una buona conduttività elettrica e termica, un'efficace schermatura elettromagnetica, un basso coefficiente di dilatazione termica e una forte anisotropia. Rispetto alla tradizionale fibra di vetro, la fibra di carbonio offre più di tre volte il modulo di Young e circa modulo doppio della fibra aramidica (Kevlar) È insolubile e non si gonfia in solventi organici, acidi o alcali, il che lo rende particolarmente adatto ad ambienti corrosivi e difficili. Un modo efficace per ridurre i costi delle applicazioni in fibra di carbonio è combinarla con materiali plastici tecnici come il nylon, creando materiali compositi ad alte prestazioni con un rapporto costo-prestazioni ottimizzato. Di conseguenza, il nylon rinforzato con fibra di carbonio è diventato un materiale importante nell'ingegneria dei compositi moderna. Il nylon è di per sé un materiale plastico ingegneristico ad alte prestazioni, ma presenta problemi di assorbimento dell'umidità, una limitata stabilità dimensionale e proprietà meccaniche ben inferiori a quelle dei metalli. Per superare queste limitazioni, il rinforzo in fibra è stato applicato fin dagli anni '70. Il nylon rinforzato con fibra di carbonio migliora significativamente la resistenza, la rigidità, la stabilità termica, la resistenza al creep, la resistenza all'usura e la precisione dimensionale. Rispetto al nylon rinforzato con fibra di vetro, il nylon rinforzato con fibra di carbonio offre un comportamento di smorzamento superiore e prestazioni meccaniche complessive. Pertanto, i compositi in nylon rinforzato con fibra di carbonio (CF/PA) si sono sviluppati rapidamente negli ultimi anni. In particolare, per la produzione additiva, SLS (sinterizzazione laser selettiva) La tecnologia è considerata uno dei metodi più adatti per la lavorazione di materiali in nylon rinforzato con fibra di carbonio. TDS per riferimento Applicazioni La nostra azienda Xiamen LFT Composite Plastic Co., Ltd. è un produttore professionale specializzato in termoplastici rinforzati con fibre lunghe (LFT e LFRT), tra cui Fibra di vetro lunga (LGF) E Fibra di carbonio lunga (LCF) serie. I nostri materiali LFT sono adatti per lo stampaggio a iniezione LFT-G, i processi di estrusione e lo stampaggio a compressione LFT-D. La lunghezza delle fibre può essere personalizzata da da 5 a 25 mm in base alle esigenze del cliente. La nostra tecnologia di impregnazione continua delle fibre ha superato ISO 9001 e IATF 16949 certificazione e i nostri prodotti sono protetti da numerosi marchi e brevetti.

- termoplastici rinforzati con fibre lunghe

- granuli di plastica rinforzata con fibra di carbonio

- fibra di carbonio lunga rinforzata pa12

- granuli di PA6 composito a fibra lunga

- polimeri pa6 lcf fibra di carbonio CFRP buon prezzo polimero

Tag :

-

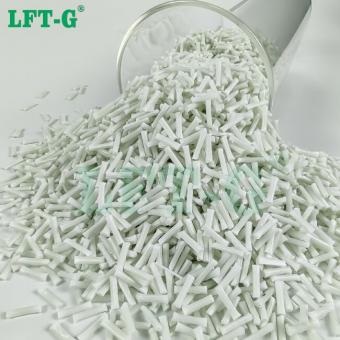

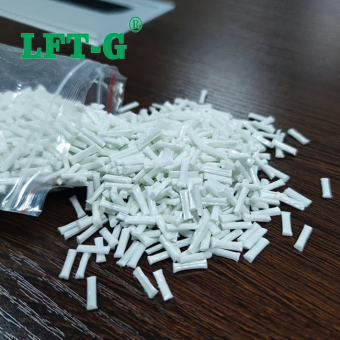

Granuli compositi in fibra di vetro lunga in polipropilene PP LFT Xiamen da 12 mmChe cosa è la fibra di vetro lunga (LGF)? Le materie plastiche rinforzate con fibre di vetro lunghe (LFT) sono materiali ingegnerizzati in cui fibre di vetro lunghe e additivi vengono incorporati in un materiale termoplastico di base. Ciò migliora significativamente la resistenza meccanica, la resistenza al calore, la stabilità dimensionale e le prestazioni complessive del materiale. Perché rinforzare con fibre di vetro lunghe? Elevata resistenza al calore: LFT aumenta significativamente le prestazioni termiche, in particolare per le plastiche a base di nylon. Ritiro ridotto e maggiore rigidità: il rinforzo in fibra limita il movimento della catena polimerica, migliorando la stabilità dimensionale e la rigidità. Maggiore resistenza agli urti: le plastiche rinforzate sono meno soggette a cricche da stress e hanno una maggiore tenacità. Elevata resistenza: le fibre di vetro lunghe aumentano la resistenza alla trazione, alla compressione e alla flessione. Resistenza al fuoco: la maggior parte dei materiali LFT sono autoestinguenti grazie agli additivi e al contenuto di fibre. Perché scegliere la fibra di vetro lunga rispetto alla fibra di vetro corta? Una maggiore lunghezza delle fibre migliora notevolmente le proprietà meccaniche. Elevata rigidità e resistenza specifiche con eccellente resistenza agli urti, ideale per applicazioni automobilistiche. Resistenza allo scorrimento e stabilità dimensionale superiori per parti di precisione. Eccellente resistenza alla fatica per componenti di lunga durata. Maggiore stabilità in ambienti caldi e umidi. Danni minimi alle fibre durante lo stampaggio grazie al movimento relativo delle fibre nello stampo. Aspetto del PP-LGF Applicazioni del PP-LGF Ricambi per auto Moduli anteriori, moduli delle portiere, meccanismi del cambio, pedali dell'acceleratore elettronico, cruscotti, ventole di raffreddamento, supporti per batterie, staffe per paraurti, piastre di protezione del sottoscocca, telai del tettuccio apribile, ecc. – in sostituzione di componenti in PA rinforzato o in metallo. Elettrodomestici Cestelli per lavatrici, staffe, ventole per aria condizionata, ecc. – in sostituzione di componenti metallici e PA rinforzati con fibra di vetro. Comunicazioni, Elettronica, Elettrodomestici Connettori ad alta precisione, componenti di accenditori, alberi di bobine, basi di relè, telai di trasformatori a microonde, alloggiamenti di elettrovalvole, componenti di scanner, ecc. Altre applicazioni Alloggiamenti per utensili elettrici, alloggiamenti per pompe/contatori dell'acqua, giranti, telai di biciclette, sci, pedali di locomotive, caschi di sicurezza, scarpe antinfortunistiche: in sostituzione di PA o PPO rinforzati con fibre corte. Scheda tecnica di riferimento Chi siamo Xiamen LFT Composite Plastics Co., Ltd. è un fornitore leader di materiali termoplastici rinforzati con fibre di vetro lunghe (LGF) e fibre di carbonio lunghe (LCF). I nostri materiali LFT supportano lo stampaggio a iniezione e l'estrusione e sono disponibili in lunghezze di fibra da 5 a 25 mm, personalizzate in base alle esigenze del cliente. Certificati ISO9001 e IATF16949, i nostri prodotti sono brevettati e ampiamente utilizzati in applicazioni automobilistiche, elettroniche, industriali e della difesa. Cosa offriamo Dati tecnici e linee guida per materiali LFT e LFRT. Raccomandazioni sulla progettazione degli stampi per una produzione ottimizzata. Supporto per stampaggio a iniezione ed estrusione per una qualità costante del prodotto.

- Riempimento in polipropilene lgf GFRP 30

- polimero termoplastico di grado vergine

- Ricambi per auto LFT-G, ricambi per elettrodomestici

- Resina PP GF prodotta in Cina plastica modificata

- composti a fibra lunga pp invece di metallo e acciaio

- stampaggio a iniezione di composito PP

Tag :

-

Xiamen LFT-G Nylon 6 Poliammide 6 composito Fibra di vetro lunga plastica modificata 12mm colore originalePanoramica del materiale PA6 Il PA6 (poliammide 6) è un materiale plastico ingegneristico ampiamente utilizzato con eccellenti prestazioni bilanciate. Le sue materie prime sono facilmente reperibili ed economiche, il che lo rende accessibile senza dover dipendere da tecnologie straniere. Tuttavia, il PA6 presenta alcune limitazioni, come l'elevato assorbimento d'acqua, una minore tenacità agli urti a bassa temperatura e una moderata stabilità dimensionale. Per superare queste limitazioni, il PA6 viene spesso rinforzato con fibra di vetro (GF) per migliorarne le proprietà meccaniche. PA6-LGF (PA6 rinforzato con fibre di vetro lunghe) 1. Influenza del contenuto di fibre di vetro Il contenuto di fibre di vetro è un fattore chiave per le prestazioni dei compositi rinforzati. Un maggiore contenuto di fibre ne aumenta la densità, assottigliando la matrice di PA6 tra le fibre. Ciò migliora la tenacità all'impatto, la resistenza alla trazione e la resistenza alla flessione. Esempio: per il PA6-LGF, l'aumento del contenuto di fibre al 35% ha aumentato la resistenza all'impatto con intaglio da 24,8 J/m a 128,5 J/m. Tuttavia, un contenuto eccessivo di fibre può ridurre la resistenza all'impatto. Anche la resistenza alla flessione migliora poiché le fibre trasferiscono lo stress e assorbono energia in caso di rottura, con risultati sperimentali che mostrano un modulo di flessione fino a 4,99 GPa per il 35% di LGF. 2. Influenza della lunghezza di ritenzione delle fibre La lunghezza delle fibre influisce significativamente sulle proprietà meccaniche. Quando la lunghezza delle fibre è inferiore alla lunghezza critica, un aumento della lunghezza migliora l'adesione resina-fibra e la resistenza al carico di trazione. Quando la fibra supera la lunghezza critica, le fibre più lunghe assorbono più energia d'impatto e migliorano la resistenza all'impatto, poiché il numero di estremità delle fibre (punti di innesco della cricca) diminuisce. Esempio: con un contenuto di fibre del 40%, l'aumento della lunghezza delle fibre da 4 mm a 13 mm ha migliorato la resistenza alla trazione da 154,8 MPa a 164,4 MPa, con una resistenza alla flessione e una resistenza all'impatto con intaglio aumentate rispettivamente del 24% e del 28%. Le fibre più lunghe di 7 mm migliorano la resistenza alla deformazione e la stabilità meccanica in condizioni di temperatura e umidità elevate. Riferimento dati tecnici (TDS) Il PA6-LGF può essere rinforzato con fibre di vetro lunghe dal 20% al 60%, a seconda dei requisiti del prodotto. Rispetto al PA6 non rinforzato, il PA6-LGF offre maggiore resistenza, resistenza al calore, resistenza agli urti, stabilità dimensionale e riduzione della deformazione. La seguente scheda tecnica mostra i dati per il PA6-LGF30. Applicazioni del PA6-LGF Il PA6-LGF è ampiamente utilizzato nei componenti automobilistici, elettronici/elettrici e nei macchinari/ingegneria. Ricambi per auto Le tendenze alla leggerezza e alla miniaturizzazione promuovono l'uso del PA6-LGF nei motori, nei sistemi elettrici e nei componenti della carrozzeria. Componenti elettronici ed elettrici L'eccellente ignifugazione e resistenza alla corrosione rendono il PA6-LGF adatto per apparecchiature di commutazione, interruttori automatici, contattori, connettori e tubi di protezione dei cavi. Parti meccaniche e ingegneristiche La buona resistenza agli urti, all'usura e le proprietà autolubrificanti consentono l'impiego del PA6-LGF in macchinari e accessori ingegneristici. Informazioni su Xiamen LFT Composite Plastics Co., Ltd. Xiamen LFT si concentra sui materiali termoplastici rinforzati con fibre di vetro lunghe (LGF) e fibre di carbonio lunghe (LCF). I nostri materiali LFT supportano lo stampaggio a iniezione (LFT-G) e l'estrusione, nonché lo stampaggio LFT-D, con lunghezze delle fibre da 5 a 25 mm. I nostri prodotti sono certificati ISO9001 e IATF16949, brevettati e ampiamente utilizzati in applicazioni automobilistiche, elettroniche, industriali e ingegneristiche.

- Materiali in resina termoplastica PA6

- granuli di nylon 6

- granuli di plastica rinforzata con fibra di vetro

- composti a fibra lunga pa6

- Stampaggio a iniezione di plastica

- Materiale rinforzato LFT-G

Tag :

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文