oggetto numero.:

PA66-NA-LCF30Pagamento:

T/T or L/C (other payment ways also can be diorigine del prodotto:

Xiamen, ChinaColore:

Original color (also can be customized)porto di spedizione:

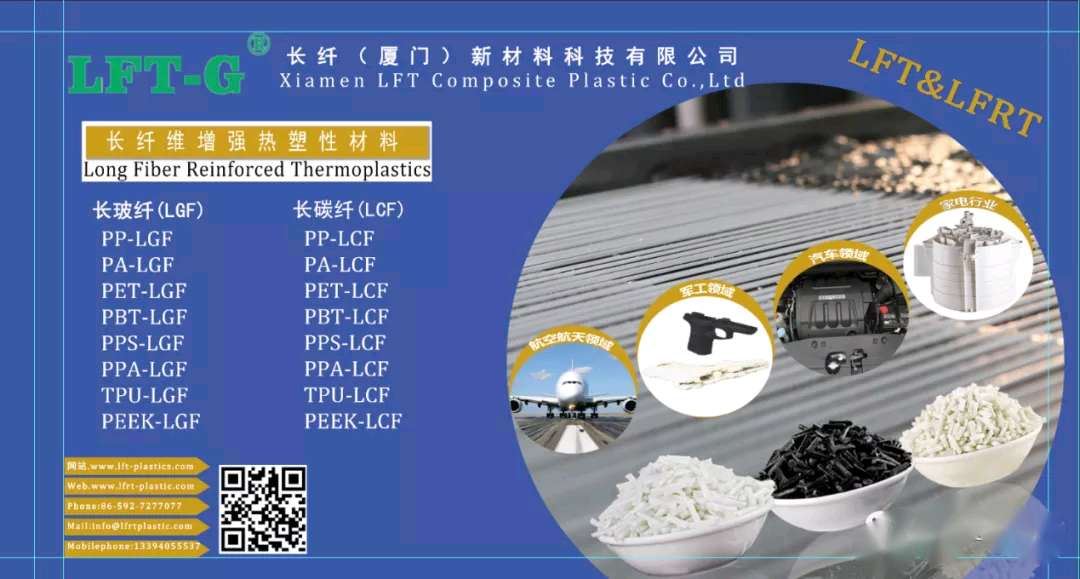

Xiamen, ChinaMaterial Introduction

In 1935, Wallace Carothers, a scientific researcher at DuPont, and his team successfully synthesized PA66 by condensation of adipic acid and adipic diamine for the first time, and DuPont completed the commercial production of PA66 fiber in 1939.

Starting in the 1950s, PA, including PA6 and PA66, was developed for the production of injection molded products to replace metal to meet the requirements of light weight and cost reduction of industrial products.

At present, PA66 is the most used PA species other than PA6.

PA66

Scientific name: Polyhexanediamide

Abbreviation: PA66

Common name: Nylon 66

PA66 has many similarities with PA6. PA66 is also a transparent to milky white granule that can take on almost any color with the addition of a colorant (masterbatch) specific for polymers.

Material properties

Similar to the basic properties of PA6, PA66 also has low specific gravity, high tensile strength, wear resistance, good self-lubrication, and excellent impact toughness.

In addition, because the number of hydrogen bonds in PA66 is more than in PA6, the intermolecular force of PA66 is stronger than the intermolecular force of PA6, which makes the internal structure of PA66 more compact than PA6, with better thermal properties, higher rigidity and toughness, better dimensional stability, lower water absorption, and more wear resistance.

However, PA66 has a higher market price than PA6 and is not as easy to process and mold as PA6.

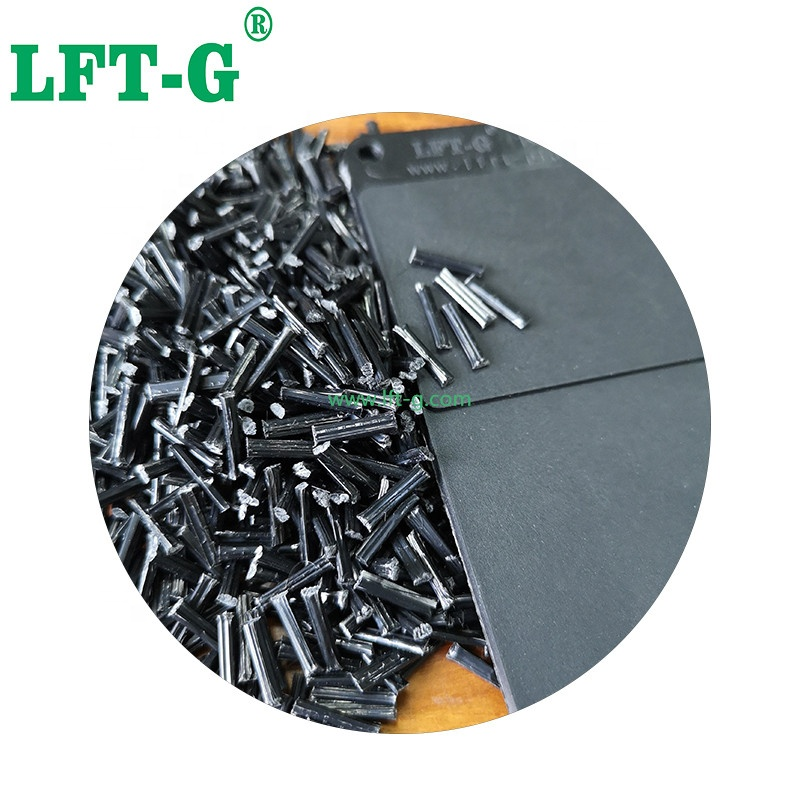

Like PA6, PA66 can also add a certain percentage of glass fiber, carbon fiber, etc. to improve the performance and meet the application needs of different products.

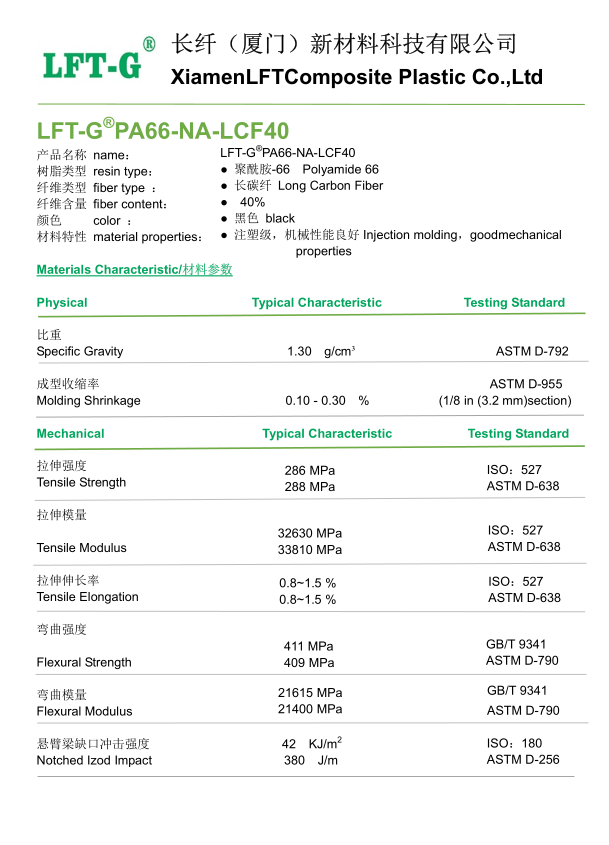

The following table is a PA66-LCF30 performance table produced by Xiamen LFT composite plastic company.

Materials Application

PA66 has higher hardness, mechanical strength, toughness, self-lubrication, friction resistance, heat resistance after the addition of carbon fiber, and is widely used in automotive parts, electrical and electronic, as well as mechanical and engineering parts and other fields.

Automotive parts

PA66's low specific gravity, high rigidity, strong toughness, heat resistance and gasoline resistance make it widely used in automotive modules, automotive structural parts, automotive interior and exterior parts, automotive transmission system and chassis shield, automotive fuel system, automotive ignition system, etc. The products involve automotive cable channel modules, structural parts of front-end components of automotive sunroof system, automotive rearview mirror bracket, automotive radiator, headlight support frame, door module, seat structural parts, seat shell and backrest, dashboard skeleton, air cooler fan, etc.

Electrical and electronics

PA66's good insulation, flame retardancy and corrosion resistance make it suitable for making various connectors, switches, sockets, terminal blocks, wire coverings, wire ties, insulating spacers, circuit breaker housings, transformer bobbins, retaining clips and motor parts after glass fiber reinforcement.

Mechanical and engineering parts

PA66's good rigidity, toughness, self-lubricating properties, heat and abrasion resistance make it suitable for manufacturing various nuts, screws, cable ties, worm gears, rotating wheels, gears, pump impellers, pulley sleeves, bushings, solenoid distribution valve seats, power tool housings, pipes, luggage racks, fan housings, appliance housings, door and window frames, cable drag chains and large machine tool baffles.

Details

| Number | Color | Length | Sample | Package | MOQ | Delivery time | Port of Loading |

| PA66-NA-LCF30 | Natural color (can be customized) | 12mm about (can be customized) | Available | 20kg/bag | 20kg | 7-15 days after shipment | Xiamen Port |

Other products you may wonder

Frequently asked questions

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A. The selection of materials depend on the requirements of the products. It is necessary to access how much the content is enhanced and how much length is more appropriate, which are depending on the performance requirements of the products.

Q. Under what circumstances can long fiber replace short fiber? What are the common alternative materials?

R. I tradizionali materiali in fibra in fiocco possono essere sostituiti con materiali LFT in fibra di vetro lunga e fibra di carbonio lunga nel caso di clienti le cui proprietà meccaniche non possono essere soddisfatte o dove si desiderano sostituti metallici superiori. Ad esempio, la fibra di vetro lunga in PP sostituisce spesso la fibra di vetro rinforzata con nylon e la fibra di vetro lunga in nylon sostituisce la serie PPS.

D. Esistono requisiti di processo speciali per la fibra di carbonio lunga per i prodotti stampati a iniezione?

R. Dobbiamo considerare i requisiti della fibra di carbonio lunga per l'ugello a vite della macchina per lo stampaggio a iniezione, la struttura dello stampo e il processo di stampaggio a iniezione. La fibra di carbonio lunga è un materiale di costo relativamente elevato e deve valutare il costo del problema delle prestazioni nel processo di selezione.