oggetto numero.:

PA6-NA-LCF50Pagamento:

T/T or L/C (other payment ways also can be diorigine del prodotto:

Xiamen, ChinaColore:

Original color (also can be customized)porto di spedizione:

Xiamen, ChinaWhat is PA6?

Nylon6 (PA6), also known as polyamide 6, English name: Polyamide6 or Nylon6, PA6 for short; That is, polycaprolactam, obtained from caprolactam ring-opening polycondensation. It is translucent or opaque opalescent resin, with superior mechanical properties, stiffness, toughness, wear resistance and mechanical shock absorption, good insulation and chemical resistance. Widely used in automotive parts, electronic and electrical parts and other fields.

What are the advantages and disadvantages of PA6?

Main advantages of PA:

1. High mechanical strength, good toughness, high tensile and compressive strength.

2. outstanding fatigue resistance, parts after repeated bending can still maintain the original mechanical strength.

3. high softening point, heat resistant.

4. smooth surface, small friction coefficient, wear-resistant.

5. corrosion resistance, very alkali and most salts, also resistant to weak acid, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants.

6. with self-extinguishing, non-toxic, odorless, good weather resistance.

7. Excellent electrical performance. Good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can be used as power frequency insulation material, even in high humidity environment still has good electrical insulation.

8. light weight, easy to dye, easy to form.

Main disadvantages of PA:

1. easy to absorb water. High water absorption, saturated water can reach more than 3%. The dimensional stability and electrical properties are affected to some extent, especially the thickening of thin-walled parts. Water absorption also greatly reduces the mechanical strength of plastics.

2. Poor light resistance. In a long-term high temperature environment, it will oxidize with oxygen in the air, turn brown at the beginning, and then break and crack.

3. injection molding technology requirements are more strict: the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing.

4. will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials.

There are many advantages of PA6, but also many disadvantages, these disadvantages limit the play of the advantages, so people thought of modifying methods to enhance its application.

What is the Long Carbon Fiber reinforced PA6?

Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries make it a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors.

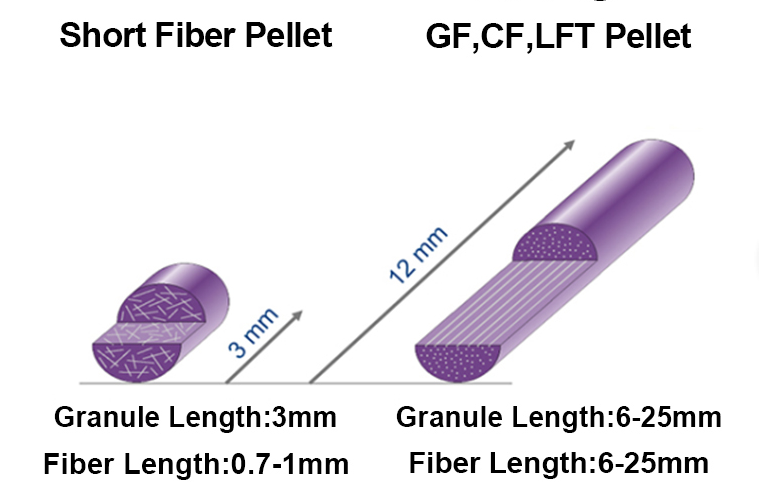

What is the differences between Long Carbon Fiber and Short Carbon Fiber?

Rispetto alla fibra corta, ha prestazioni più eccellenti nelle proprietà meccaniche. È più adatto per prodotti di grandi dimensioni e parti strutturali. Ha 1-3 volte superiore (tenacità) rispetto alla fibra corta e la resistenza alla trazione (forza e rigidità ) è aumentata di 0,5-1 volte.

TDS solo per riferimento

Casi applicativi

Dettagli del prodotto

| Numero | Colore | Lunghezza | MOQ | Campione | Pacchetto | Porto di carico | Tempi di consegna |

| PA6-NA-LCF50 | Colore originale o come richiesto | Circa 12 mm | 20 kg | Disponibile | 20 kg/sacco | Porto di Xiamen | 7-15 giorni dopo la spedizione |

Domande frequenti

1. Il prodotto è facile da fragilizzare, quindi passare all'uso di materiali termoplastici rinforzati con fibre lunghe può risolvere questo problema?

R: Le proprietà meccaniche complessive devono essere migliorate. Le caratteristiche della fibra di vetro lunga e della fibra di carbonio lunga sono i vantaggi delle proprietà meccaniche. Ha 1-3 volte superiore (tenacità) rispetto alla fibra corta e la resistenza alla trazione (forza e rigidità) è aumentata di 0,5-1 volte.

2. Esistono particolari requisiti di progresso per i prodotti per stampaggio ad iniezione in fibra di carbonio lunga?

A: Dobbiamo considerare i requisiti della fibra di carbonio lunga per l'ugello a vite della macchina per lo stampaggio a iniezione, la struttura dello stampo e il processo di stampaggio a iniezione. La fibra di carbonio lunga è un materiale di costo relativamente elevato e deve valutare il problema delle prestazioni in termini di costi nel processo di selezione.

3. Il costo dei prodotti a fibra lunga è più elevato. Ha un alto valore di riciclaggio?

R: Il materiale termoplastico LFT a fibra lunga può essere riciclato e riutilizzato molto bene.