-

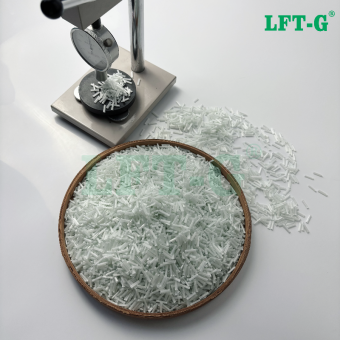

Pellet di PA6 in fibra di vetroNel industria automobilistica ry , viene utilizzato perché è più economico e leggero del metallo. In macchine , viene utilizzato rispetto ad altri materiali per la sua elevata flessibilità e durevolezza.

- nylon 6 pa6

- nylon rinforzato con fibre

- fibra di vetro rinforzata

- composti di nylon

- nylon rinforzato con fibra di vetro

- plastica rinforzata con fibra di vetro

Tag :

-

Pellet di PA66 in fibra di vetroNylon 6,6 , è una versione più cristallina del nylon 6. È anche chiamato poliammide 66 o PA 66. Ha proprietà meccaniche migliorate grazie alla sua struttura molecolare più ordinata, il Nylon 66 per lavorazioni meccaniche ha resistenza alla temperatura migliorata E tassi più bassi di assorbimento dell'acqua rispetto al nylon 6 standard.

- nylon 66 pa66

Tag :

-

Pellet PA12 Fibra di vetroPa12 gf20 è un tipo di plastica ingegneristica costituita da composti di poliammide 12 (PA12) rinforzati con il 20% di fibre di vetro. È un materiale ad alte prestazioni che presenta numerosi vantaggi rispetto al nylon 12 puro, come maggiore resistenza, rigidità, resistenza termica, resistenza chimica e proprietà elettriche Il Pa12 gf20 è ampiamente utilizzato per varie applicazioni in diversi settori, come automobilistico, aerospaziale, medico, elettrico e industriale .

- nylon 12 pa12

Tag :

-

Pellet PBT Fibra di vetroPBT GF30 è un materiale composito termoplastico ad alte prestazioni che offre eccezionali resistenza meccanica e resistenza al calore Questo materiale composito è creato rinforzando polibutilentereftalato (PBT) resina con 30% fibre di vetro Il PBT GF30 trova applicazione in vari settori grazie alle sue proprietà e ai suoi vantaggi unici.

- resina di polibutilene tereftalato

- polimeri rinforzati con fibra di vetro

- compositi polimerici rinforzati con fibra di vetro

- fibra pbt

Tag :

-

Pellet di TPU in fibra di vetroTPU Il nome completo della plastica è poliuretano termoplastico. Si tratta di una linea di materie plastiche appartenente al gruppo dei termoplastici, lavorata mediante processo di fusione. Tra queste, la plastica TPU si distingue per le proprietà sia della gomma che della plastica, come flessibilità, tenacità e buona resistenza alla trazione. I campi di applicazione tipici del TPU includono la tecnologia automobilistica, i cavi e alcune attrezzature sportive.

- termoplastico rinforzato con fibre

- poliuretano termoplastico tpu

- poliuretano termoplastico tpu

- rinforzato con fibra di vetro

- fibra di vetro rinforzata

- compositi rinforzati con fibra di vetro

Tag :

-

Pellet di ABS in fibra di vetroABS Lo stampaggio a iniezione si riferisce al processo di iniezione di plastica ABS fusa in uno stampo ad alte pressioni e temperature. Esistono numerose applicazioni di stampaggio a iniezione di ABS, poiché è una plastica ampiamente utilizzata e può essere trovata in industrie automobilistica, dei beni di consumo e delle costruzioni per citarne alcuni.

- barre d'armatura in polimero rinforzato con fibra di vetro

- pannello in cemento armato con fibra di vetro

- plastica ABS

- pellet di resina ABS

- plastica ingegneristica

Tag :

-

Ampia gamma di applicazioni in polimero di fibra di vetro PPA resistente alle alte temperaturePoliftalamide (PPA) è una poliammide aromatica semicristallina. Si trova nella poliammide, o nylon , famiglia. Rispetto al Nylon 6/6, è più resistente, più rigido, meno sensibile all'umidità e con maggiori capacità termiche Inoltre, ha una notevole resistenza a affaticamento chimico E scorrimento meccanico .

- Plastica PPA rinforzata

- Materiale per stampaggio a iniezione PPA

- Componenti elettronici termoplastici

- fibra di vetro ppa

- fibra di vetro contro fibra di carbonio

- polimero aerospaziale

Tag :

-

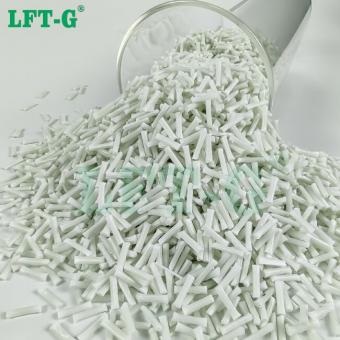

Pellet di plastica rinforzata in polipropilene riempito con fibre di vetro lungheGrado: General grade, Heat-resistant grade, UV-resistant grade, Toughen resistant grade Fiber specification: 20%-70%

- PP GF30 modificato di grado generale

- Polimeri PP a taglio lungo resistenti al calore

- PP LFT resistente ai raggi UV per elettrodomestici

- PP di grado resistente con riempitivo in fibra di vetro

- Composti PP di grado di iniezione invece di metallo

- Ampia gamma di applicazioni Resina termoplastica PP

Tag :

-

Riempimento di grado generale HPP Fibra di vetro lunga LGF Polipropilene modificato Materiali rinforzati con plasticapolipropilene , also known as PP , is a polyolefin or saturated polymer . It is a low-density thermoplastic with good resistance to heat. Other characteristics of PP include: chemical resistance, elasticity, toughness, fatigue resistance, and electrical insulation capability.

- PP GF30

- soluzioni di sostituzione dei metalli

- materiali lft

- pp caricato con fibra di vetro

- stampaggio a iniezione di pp

- pellet pp

Tag :

-

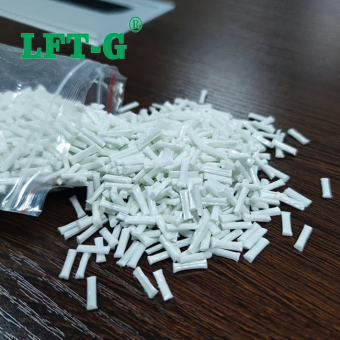

LFT-G PA6 Poliammide6 nylon6 riempimento fibra di vetro lunga40 colore originale per parti automobilisticheNylon rinforzato con fibra di vetro lunga PA6 e PA6-LGF PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificates

- Composito di poliammide 6

- resina termoplastica lgf

- PA6 ad alto impatto

- stampaggio a iniezione di plastica

- riempimento in pa6 fibra di vetro lunga

- Plastica rinforzata

Tag :

-

LFT-G nylon66 modificato PA66 riempimento composti di fibre di vetro lunghe apparecchi elettroniciNylon rinforzato con fibra di vetro lunga PA66-LGF PA66, or Nylon 66, is a high-performance polyamide widely used in engineering plastics. It offers excellent mechanical properties including tensile strength, flexural strength, and impact resistance, along with superior thermal and chemical stability. With lightweight, high wear resistance, good electrical insulation, and self-extinguishing properties, PA66 is ideal for automotive, electrical, industrial equipment, and construction applications. Why Reinforce PA66 with Long Glass Fiber? While PA66 is versatile, it has limitations: high water absorption, low compressive strength when wet, poor alkali resistance, and potential deformation at ultra-low temperatures. Long glass fiber (LGF) reinforcement addresses these challenges. Adding LGF significantly improves impact resistance, thermal deformation resistance, mechanical performance, molding processability, and chemical resistance. LGF acts as a robust internal skeleton, enhancing the durability and reliability of PA66 components. PA66-LGF Technical Datasheet *The datasheet is tested by Xiamen LFT and provided for reference only.* Applications of PA66-LGF PA66 reinforced with 30% long glass fiber is ideal for high-performance applications such as: Automotive components and structural parts Power tool housings and mechanical parts Industrial equipment components For specialized applications, please consult our technical team. PA66-LGF Product Details Number Color Length Sample MOQ Port of Loading Delivery Time Payment Terms PA66-NA-LGF30 Original color (customizable) 12mm (customizable) Available 25kg Xiamen Port 7-15 days after shipment Discussed Xiamen LFT Composite Plastic Co., Ltd Xiamen LFT Composite Plastic Co., Ltd. is a leading manufacturer specializing in long fiber reinforced thermoplastics (LFT & LFRT), including Long Glass Fiber (LGF) and Long Carbon Fiber (LCF) series. Our thermoplastic LFT can be applied in LFT-G injection molding, extrusion molding, and LFT-D molding. We provide products according to customer requirements with fiber lengths from 5 to 25mm. Our continuous infiltration reinforced thermoplastics have passed ISO9001 & 16949 certifications and hold numerous national patents and trademarks. Our Services Technical parameters and leading-edge design of LFT & LFRT materials Mold front design recommendations Technical support for injection molding and extrusion molding processes

- Apparecchio elettronico a bassa deformazione

- pellet PA66 autoalimentati

- pellet PA66 rinforzati ad alta resistenza e tenacità

- i migliori granuli di fibra di vetro lunga pa66 lgf30

- PA66 6 pellet lgf a doppia vite

- Applicazione dei granuli di PA66 a fibra lunga

Tag :

-

Composti di acido polilattico PLA Resina termoplastica a fibra di vetro lunga per l'ingegneriaPLA e LGFPLA – Bioplastiche ecologiche e rinforzate PLA (Polylactic Acid) is a non-natural polyester and one of the most promising "green plastics." Known for its biocompatibility, biodegradability, and high mechanical strength, PLA can be completely degraded by microorganisms into CO₂ and water, making it non-toxic and environmentally friendly. PLA offers mechanical properties similar to polypropylene, while providing the gloss, clarity, and processability of polystyrene. With a lower processing temperature than polyolefins, PLA can be molded via injection molding, extrusion, blow molding, spinning, and other general plastic processes. Its applications range from disposable packaging and fibers to nonwovens, and extend to medical, chemical, pharmaceutical, and 3D printing industries. Long Glass Fiber Reinforced PLA (LGFPLA) Glass fiber is an inorganic non-metallic material with excellent insulation, heat resistance, corrosion resistance, and mechanical strength. When used to reinforce PLA, it creates Long Glass Fiber PLA (LGFPLA), a high-performance thermoplastic composite with glass fibers 10–25mm long, forming a 3D structure for superior strength and stability. LGFPLA is available as columnar pellets, typically 12mm (for injection molding) or 25mm (for compression molding) in length, with glass fiber content from 20% to 60%. Colors can be customized to match client requirements. Advantages of LGF vs SGF (Long Fiber vs Short Fiber PLA) Longer fiber length improves mechanical properties and part durability. High specific stiffness and strength, with excellent impact resistance — ideal for automotive parts. Improved creep resistance and dimensional stability for precise molding. Outstanding fatigue resistance and long-term reliability. Stable performance in high temperature and humid environments. Minimal fiber damage during molding due to fiber mobility within the mold. Technical Specifications Product Number Color Length Fiber Specification Package Sample Port of Loading Delivery Time PLA-NA-LGF Natural or customizable 6–25mm 20%–60% 25kg/bag Available Xiamen Port 7–15 days after shipment Lab & Factory Xiamen LFT Composite Plastic Co., Ltd. Xiamen LFT Composite Plastic Co., Ltd. specializes in developing and producing long glass fiber (LGF) and long carbon fiber (LCF) reinforced thermoplastic composites (LFT-G, LFRT, LFT). Our materials are lightweight, high-strength, impact-resistant, and environmentally friendly, offering excellent corrosion and chemical resistance along with superior molding performance. Our products are used across industries including automotive, aerospace, military, electrical, medical, sports equipment, and daily consumer goods, producing components such as gears, rollers, pulleys, pump impellers, fan blades, and more.

- PLA plastica rinforzata lgf produzione pla

- Materiali modificati per stampaggio a iniezione LFT-G PLA

- composti di fibre di vetro lunghe resina pla basica

- Pellet di PLA di fibra lunga 30 prodotti in Cina

- Produttore di polimeri PLA auto-adesivi, vendita diretta

- Pellet di PLA puro grado vergine lft

Tag :

e-mail

e-mail italiano

italiano English

English français

français Deutsch

Deutsch русский

русский español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文