nuovo blog

At present, these manufacturers have invested a lot of manpower and material resources in the production of this type of material research and development and market development work.

What is long glass fiber modified PP? Compared to short glass fiber reinforced PP and what advantages? Where are they being used?

Here are the answers.

PP plastic

As one of the general plastic materials, PP has excellent comprehensive properties, good chemical stability, better molding performance and relatively low price. But PP has the disadvantages of low strength, modulus, hardness, low temperature impact resistance strength, forming shrinkage, easy aging and so on.

Generally speaking, the tensile strength of PP material is between 20M and 30MPa, the bending strength is between 25M and 50MPa, and the bending modulus is between 800M and 1500MPa. Therefore, it is modified to make it adapt to the demand of the product. Nowadays, each kind of modified PP has a large number of applications in the field of household appliances and vehicles.

LGF

Glass fiber (or fiber glass) is a kind of inorganic nonmetallic material with excellent performance. The advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength, but the disadvantages are brittle and poor wear resistance. One of the main uses of glass fiber is to reinforce composite materials. Long glass fiber generally refers to the length of more than 10mm glass fiber.

LGF reinforced PP plastic

Long glass fiber reinforced PP plastic refers to contain glass fibre length in 10 to 25 mm of modified PP composite materials, forms through injection molding process such as glass fiber length is greater than 3.1 mm of three-dimensional structure, abbreviated as LGFPP. There are a lot of information will be at home and abroad Long fiber reinforced thermoplastic LFT fell short for (i.e., Long - fiber reinforce thermoplastic). From the material definition, LGFPP belongs to a kind of LFT.

As the vehicle module carrier material, the material can not only effectively improve the rigidity, impact strength, creep resistance and dimensional stability of the product, but also can make complex vehicle module products.

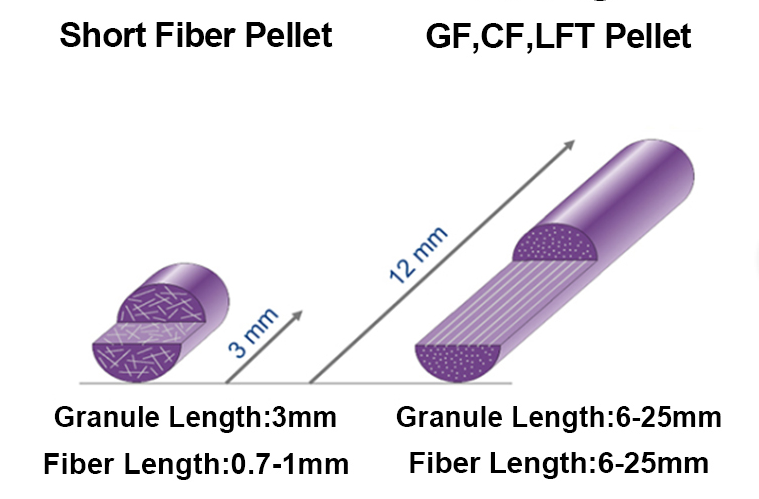

Particle morphology of reinforced LGF-PP

It is usually a columnar particle with a length of 12 or 25 mm and a diameter of about 3 mm. The 12mm or so length of the grain is mainly used for injection molding, and the 25mm or so length of the grain is mainly used for pressure molding. In this particle, the glass fiber has the same length as the particle, the content of the glass fiber can vary from 20 to 70 percent, and the color of the particle can be matched according to the customer's requirements.

Why do some areas use long glass fiber reinforced PP instead of short glass fiber reinforced PP?

Compared with short fiber reinforced thermoplastic composites, LFT has the following advantages:

• Long fiber length, significantly improve the mechanical properties of products.

• High specific stiffness and strength, good impact resistance, especially suitable for automotive applications.

• Improved creep resistance, good dimensional stability, high component forming accuracy.

• Excellent fatigue resistance.

• Better stability in hot and humid environments.

• The fiber can be relatively moved in the molding mold during the molding process, and the fiber damage is small.

Where is long glass fiber reinforced PP often used?

The Automobile Industry

Home Appliance Industry

Washing machine drum, washing machine triangle bracket, one brush machine drum, air conditioning fan, etc., used to replace short glass fiber reinforced PA, APS metal materials.

Communications, electronics, electrical industries

High-precision connectors, igniter components, coil shaft, relay base, microwave transformer coil frame/frame, electrical connector, solenoid valve package, scanner components, etc.

other

Alloggiamento dell'utensile elettrico, alloggiamento della pompa dell'acqua o del contatore dell'acqua, girante, scheletro della bicicletta, sci, pedali della locomotiva a terra, elmetto di sicurezza militare/civile, scarpe di sicurezza Baotou, ecc., utilizzato per sostituire PA rinforzato con fibra di vetro corta, PPO, ecc.