Come scegliere il giusto grado di PEEK

Come scegliere il giusto grado di polietere etere chetone (PEEK)

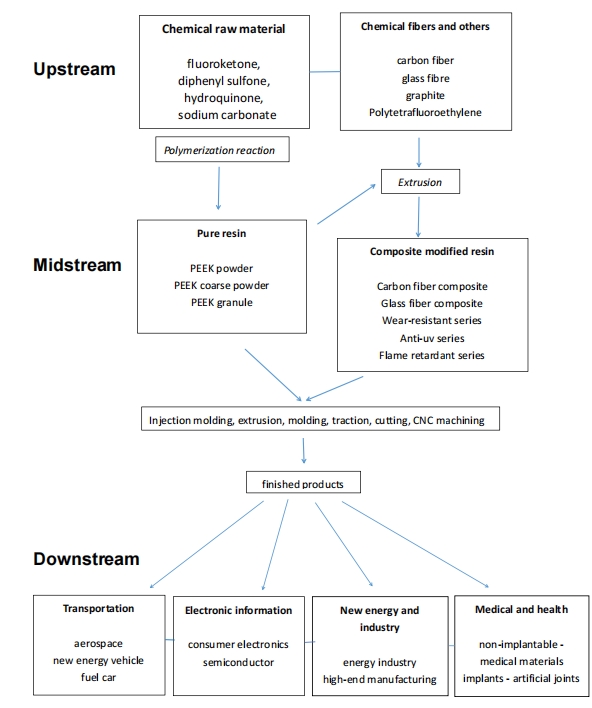

Il polietere etere chetone (PEEK) è un polimero ad alta temperatura rinomato per le sue eccezionali proprietà meccaniche, termiche e chimiche. È ampiamente utilizzato nei settori aerospaziale, automobilistico, medico ed elettronico.

Ma cosa distingue il PEEK dalle altre materie plastiche ad alte prestazioni? Perché gli ingegneri scelgono il PEEK rispetto alle alternative?

In questa guida spiegheremo come viene prodotto il PEEK e qual è la sua struttura molecolare, aiutandoti a scegliere il grado di PEEK ideale per le tue applicazioni.

Cos'è la plastica PEEK?

Il PEEK appartiene alla famiglia dei poliarileterchetoni (PAEK), che comprende PEK, PEEK, PEEKK, PEKK e PEKEKK. Tra questi, il PEEK è il più utilizzato e prodotto su larga scala.

L'abbreviazione

SBIRCIARE

rivela la sua struttura chimica:

-

Poli:

molte unità ripetute (polimero)

-

Etere:

un legame di ossigeno nella catena

-

Etere:

un altro collegamento dell'ossigeno

-

Chetone:

un legame del gruppo carbonile (C=O)

Questa specifica disposizione conferisce al PEEK le sue eccezionali proprietà. Fin dalla sua commercializzazione nei primi anni '80 da parte di Imperial Chemical Industries (ICI, ora parte di Victrex PLC), il PEEK è completamente riciclabile.

Confronto delle prestazioni con altri polimeri ad alta temperatura

Proprietà fisiche

-

Termoplastico tecnico semicristallino ad alte prestazioni

-

Ottima resistenza ai liquidi e alla fatica

-

Insolubile nei solventi comuni e resistente all'idrolisi

-

Può resistere al vapore o all'acqua ad alta pressione per 1.000 ore senza degradazione

-

Elevata stabilità dimensionale, purezza intrinseca e biocompatibilità

Proprietà meccaniche

-

Eccellente resistenza alla trazione, tenacità e resistenza allo scorrimento

-

Proprietà flessionali e di trazione bilanciate per applicazioni ad alto carico e ad alta temperatura

-

Mantiene il modulo di flessione a temperature molto elevate

-

Componenti leggeri adatti ad ambienti difficili

Proprietà termiche

-

Alto punto di fusione (Tm): 343°C

-

Elevata temperatura di transizione vetrosa (Tg): 143°C

-

Temperatura di utilizzo continuo: fino a 260°C

Proprietà elettriche

-

Elevata resistività di volume e superficie

-

Eccellenti prestazioni isolanti in un ampio intervallo di temperature

Infiammabilità

-

Classificazione di infiammabilità V0 a 1,45 mm di spessore

-

Indice limite di ossigeno (LOI): 35%

-

Basse emissioni di fumo e gas tossici

Materiali rinforzati

-

Le fibre di vetro o di carbonio migliorano il modulo di flessione, la resistenza allo scorrimento, la conduttività termica e la temperatura di deformazione termica

-

Il PEEK rinforzato con fibra di carbonio mantiene le prestazioni a 299°C con resistenze alla trazione fino a 29.000 psi (~200 MPa)

PEEK vs. altri polimeri ad alta temperatura

-

Fluoropolimeri:

Il PEEK eccelle in resistenza alla trazione, temperatura di deformazione termica, temperatura di esercizio, adesione, lavorabilità ed emissioni di gas tossici; è leggermente inferiore in resistenza chimica, costo, tenacità e resistenza ai raggi UV.

-

Solfuro di polifenilene (PPS):

Il PEEK ha una resistenza al calore, una tenacità e un controllo delle sbavature superiori.

-

Polietersulfone (PES):

Il PEEK offre migliori prestazioni in termini di temperatura, resistenza all'usura, resistenza chimica e resistenza alla fatica.

In genere il PEEK non viene miscelato con altri polimeri, ma può formare miscele miscibili con altri PAEK e polieterimmidi (PEI).

-

Miscele PEEK/PEI:

Tg più alto

-

Miscele con PES e PPS:

alta compatibilità

Limitazioni del PEEK

-

Costo elevato: ideale per applicazioni ad alte prestazioni

-

Richiede lavorazione ad alta temperatura

-

Vulnerabile agli acidi solforico, nitrico e cromico concentrati

-

Suscettibile agli alogeni e al sodio

-

Bassa resistenza ai raggi UV

Applicazioni del polietere etere chetone (PEEK)

Il PEEK è utilizzato nei settori aerospaziale, automobilistico, elettrico, medico, chimico e ingegneristico. I componenti tipici includono cuscinetti, componenti di pistoni, pompe, colonne HPLC, valvole di compressori e isolamento dei cavi.

Industria automobilistica

-

Alternativa leggera, silenziosa e funzionalmente integrata ai metalli

-

Eccellente interazione superficie asciutta/lubrificata, prestazioni meccaniche, resistenza alla fatica

-

Applicazioni: guarnizioni, cuscinetti e parti mobili di unità pistone in trasmissioni, freni e sistemi AC

Aerospaziale

-

Sostituzione dell'alluminio e di altri metalli

-

Parti di grandi dimensioni e ad alta precisione possono essere stampate in modo efficiente senza assemblaggio

-

Applicazioni:

-

Componenti del motore: resistono alle alte temperature e all'attrito

-

Parti esterne: resistenza all'erosione della pioggia

-

Parti interne: ignifughe, bassa emissione di fumo/tossicità

-

Sistemi elettrici: protezione di cavi e fibre

Medicina e assistenza sanitaria

-

Elevata resistenza all'usura, al calore, agli agenti chimici e all'isolamento elettrico

-

Applicazioni: strumenti dentali, endoscopi, apparecchiature per dialisi

-

Esempi:

-

Maniglie per siringhe odontoiatriche e scatole sterili sostituiscono l'alluminio

-

Resiste fino a 3.000 cicli di sterilizzazione ad alta pressione a ~134°C

-

Mantiene la resistenza meccanica e la stabilità idrolitica

-

Miglioramento della biocompatibilità degli impianti

Elettrico ed elettronico

-

Eccellente isolante per un'elevata affidabilità in presenza di variazioni di temperatura, pressione e frequenza

-

Riduce al minimo la contaminazione nella lavorazione dei wafer

-

Applicazioni:

-

Prese per connettori coassiali

-

Potenziometri microregolabili montati in superficie (SMD)

-

Isolatori per apparecchiature di controllo ambientale sottomarino

Altri mercati chiave

-

Supera i metalli nei componenti industriali, chimici e di lavorazione

-

PEEK approvato dalla FDA per applicazioni a contatto con gli alimenti

-

Esempi:

-

Sostituzione delle giranti in acciaio inossidabile nelle pompe rigenerative

-

Raccordi per tubi e flessibili per pressioni fino a 25.000 psi e temperature fino a 260°C