La tecnologia termoplastica a fibra lunga (LFT) continua a svilupparsi. Mentre le applicazioni automobilistiche mantengono la loro posizione dominante sul mercato, altre aree industriali sono sempre più attratte dalla promessa di leggerezza e alta resistenza: i compound PP LFT, ad esempio, possono offrire alternative a basso costo ai metalli e polimeri ingegnerizzati tecnici più costosi.

Penetrazione continua di LFT PP compfondi nel settore automobilistico

Secondo un rapporto pubblicato da AMI Consulting nel settembre 2021, la penetrazione del mercato del PP continua a crescere. Il rapporto quantifica l'uso di LFT PP in forma granulare (LDT-G) e LFT PP composito diretto in linea (LDT-D) e tiene traccia dell'utilizzo in tutto il mondo. LFT PP è ampiamente utilizzato nei supporti per l'avantreno automobilistico, nei supporti per cruscotti, nei pannelli delle portiere, nelle console, nei pedali, nelle protezioni sottoscocca e in molte altre applicazioni automobilistiche, ha affermato la società. Una caratteristica di queste applicazioni è che LFT PP sta sostituendo l'acciaio, riducendo così il peso, o tecnopolimeri più costosi.

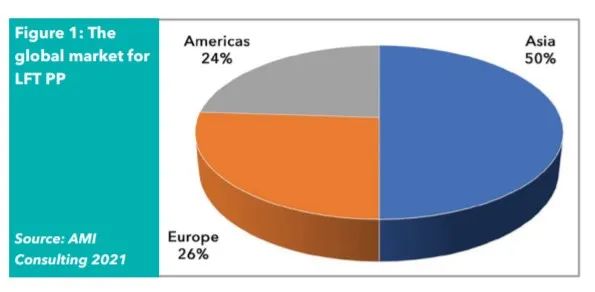

AMI Consulting prevede che LFT PP manterrà una forte crescita fino al 2025. Sebbene i tassi di crescita varino a seconda dei segmenti di applicazione, degli OEM automobilistici e dei mercati geografici. In passato, l'Europa era leader nelle vendite di LFT, ma le cose sono cambiate. L'Asia rappresenta il 50% della domanda globale di PP LFT nel 2020, rispetto al 26% in Europa e al 24% nelle Americhe (Tabella 1), secondo il rapporto.

Tabella 1: distribuzione globale del mercato LFT PP negli ultimi 20 anni

Una delle aree di applicazione in più rapida crescita è quella delle porte per ascensori per bauli auto, che variano nel design da tutto metallo a quasi nessun metallo. Nei progetti privi di metallo, LFT PP viene utilizzato per fornire resistenza strutturale ed è integrato da PP ad alte prestazioni per fornire una pelle esterna verniciabile. Nelle applicazioni più gravose, gli elementi LFT PP all'interno della struttura sono a vista e richiedono quindi una buona finitura estetica. Le porte degli ascensori in plastica sono particolarmente preziose per i produttori di auto elettriche come nuovo modo per ridurre il peso.

The shift to electric and hybrid vehicles, while threatening some existing polymer applications, is also creating new opportunities for LFT PP as designers are rethinking concepts and adopting new approaches. The report cites the example of Tesla's "frunk" -- a back-up or storage compartment located at the front. This would make use of space in the front of the vehicle for storage, but would need to be designed with the ability of a traditional car's front end to absorb the impact of a crash.

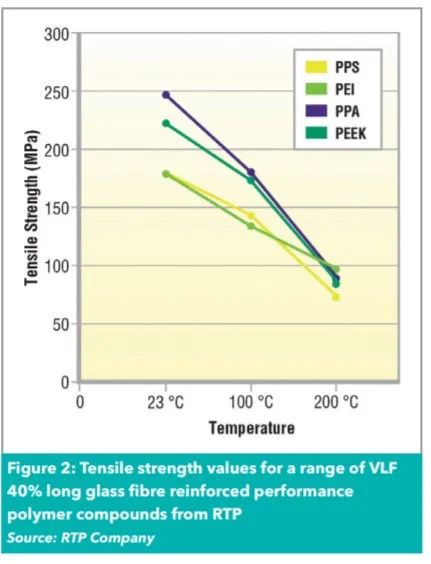

The strong interest in LFT materials from various industries is confirmed by RTP Inc., which offers a wide range of LFT materials. "Replacement metal parts or over-engineered short fiberglass compounds continue to be major growth opportunities," said Zach Halverson, Manager of the company's structured products business. For example, long fiber polypropylene compounds can often successfully replace short glass fiber polyamide compounds to provide a lower cost and lower density solution." Long fiber technology in engineering and high performance based polymers such as PEEK, PPA, PEI and PPS, these combine the desired mechanical and thermal properties of the polymer with the added benefit of long fibre reinforcement. They are said to be a good alternative to metals in particularly demanding environments, such as in the oil and gas industry, where other materials cannot meet demand (Table 2)

Table 2: Long glass fiber reinforced polymer compounds with tensile strength range of 40%.

Halverson said the automotive industry remains the largest consumer of long-fiber thermoplastics, and any changes in the industry will affect its use.

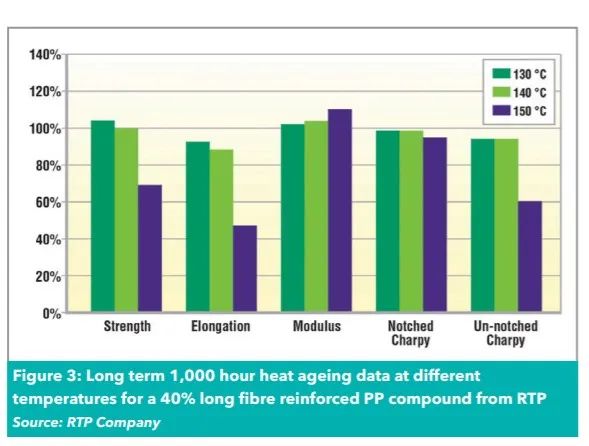

As the primary end user of LFT, the performance needs of the automotive industry are a key driver of LFT development. Current challenges include increasingly stringent VOC limits, the ability to withstand long-term thermal aging of more than 1,000 hours at 150°C (Figure 3), stronger UV-resistant linearity, and the ability to achieve A highly aesthetic Class A surface finish directly outside the mold. Usually several of these requirements need to be met in an application process.

Figure 3: Long-term 1,000-hour thermal aging data of 40% long fiber reinforced PP composites from RTP at various temperatures.

To address these automotive challenges, Xiamen LFT composite plastic Co.,ltd's product development team is constantly experimenting with extensive experimental combinations of new formulations, and developed anti - UV grade products.

Long fibre technology is now a mature area of the thermoplastic market. Nearly 40 years have passed since long fibre reinforced thermoplastics were first introduced in the early 1980s. So the industry is definitely at or reaching a stage of maturity, particularly in commodities for materials such as long glass fibre polypropylene, where it has a large number of suppliers. Most market research reports indicate that the long fiber materials market will continue to grow at a high single-digit CAGR for the foreseeable future. Growth has been prominent in the automotive industry, where long fibre materials are valued for their lightweight capabilities in metal replacement scenarios. The growth in material use has coincided with an increase in the global production of cars and trucks. Transportation is not the only market segment focusing on weight loss. Consumer discretionary products, especially sports and industrial equipment, are moving toward more portable devices that make life easier for users. While lightweight is often the first choice for product designers, the change to metal composites offers many other benefits. Cost reduction is a major driver, easily achieved when switching from metal manufacturing to injection molding production. The metal-like properties of long fiber composites, combined with their excellent durability, can also produce very strong products. These products are also usually made with recycling capabilities in mind. In a world increasingly concerned with the life cycle of materials, this is a necessary consideration.

LFT is valued for its lightweight and strength in applications such as off-road vehicles.