nuovo blog

Quando prendi in mano il tuo telefono, smonti un pezzo di ricambio per auto o guardi la custodia di un elettrodomestico, potresti non renderti conto che nascosto all'interno di questi prodotti di plastica apparentemente ordinari si nasconde una sorta di "armatura invisibile" — fibra di vetro (GF) Da PP + 20% GF a PA + 60% GF, queste fibre di rinforzo sostengono silenziosamente la matrice plastica, proprio come le barre d'acciaio all'interno del calcestruzzo.

Oggi scopriamo il mistero di

fibre di vetro lunghe

,

fibre di vetro corte

, E

fibre di vetro piatte

e scopri come trasformano la plastica in materiali che raggiungono il perfetto equilibrio tra resistenza e flessibilità.

Fibra di vetro: il “codice di rinforzo” delle materie plastiche

Ciò che rende la fibra di vetro il "partner ideale" delle materie plastiche ingegneristiche risiede nella sinergia fibra-resina, che compensa le debolezze intrinseche delle materie plastiche pure:

1. Rinforzo meccanico:

Come aggiungendo uno scheletro nascosto alla plastica, la resistenza alla trazione può essere migliorata dal 20% al 100%, mentre la resistenza all'impatto può persino avvicinarsi al livello dei metalli.

| Materiale |

Resistenza alla trazione

|

Standard di prova

|

| Resina PP pura | 30 MPa |

ASTM D-638

|

|

PP rinforzato con fibra di vetro corta

|

90 MPa |

ASTM D-638

|

| PP rinforzato con fibra di vetro lunga | 150 MPa |

ASTM D-638

|

I dati sui materiali variano a seconda del marchio.

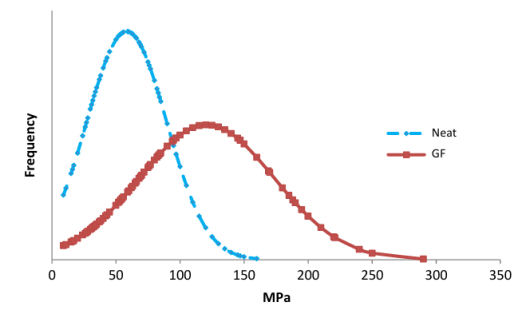

Questo grafico confronta il distribuzione della forza Di polimero pulito (linea tratteggiata blu) e polimero rinforzato con fibra di vetro (linea rossa). Il polimero puro mostra valori di resistenza inferiori concentrati attorno 70–90 MPa , mentre il polimero rinforzato con fibra di vetro presenta una distribuzione più ampia con resistenze molto più elevate, che si estendono fino a circa 300 MPa Ciò indica che il rinforzo in fibra di vetro migliora significativamente le prestazioni meccaniche del materiale.

2. Resistenza alla deformazione: sopprime il restringimento della resina, rendendo i prodotti meno inclini a deformarsi sotto alte temperature e stress, con un tasso di restringimento controllabile fino a un minimo di 0,15% .

3. Bilanciamento dei costi: rispetto alle materie plastiche ingegneristiche pure, i materiali rinforzati con fibre possono raggiungere alte prestazioni a costi inferiori Ad esempio, utilizzando fibra di vetro lunga PA A sostituire il metallo In parti di automobili riduce il peso di 58% riducendo i costi del 30%. Tuttavia, diverse forme di fibra di vetro conferiscono "miglioramenti" molto diversi alla plastica. La scelta giusta può raddoppiare le prestazioni del prodotto, mentre quella sbagliata può causare problemi come l'esposizione delle fibre e la fragilità.

Tipo di fibra: lunga, corta o piatta

Le fibre di vetro più comunemente utilizzate sono la fibra di vetro lunga, la fibra di vetro corta e la fibra di vetro piatta. Differiscono significativamente per morfologia, prestazioni, metodi di lavorazione e scenari applicativi, il che si riflette anche nelle loro caratteristiche strutturali:

| Tipo | Intervallo di lunghezza | Caratteristiche morfologiche | Vantaggi principali |

|---|---|---|---|

| Fibra di vetro lunga | 5–25 mm (comunemente 6–12 mm) | Filamenti continui, elevata integrità | Campione di forza, eccellente resistenza alla fatica |

| Fibra di vetro corta | 0,1–1 mm (comunemente 0,2–0,5 mm) | Segmenti corti, facili da disperdere | Prestazioni equilibrate e facili da elaborare |

| Fibra di vetro piana | 0,5–5 mm (personalizzabile) | Nastro piatto, ampia superficie | Superficie liscia, esperto resistente alle deformazioni |

Le fibre di vetro lunghe sono come "barre di acciaio continue", che formano una rete continua all'interno della resina e trasmettono efficacemente lo stress, motivo per cui la loro la resistenza all'impatto è superiore del 50%–100% rispetto a quella delle fibre di vetro corte. Le fibre di vetro corte assomigliano a "scorie di acciaio rotte": sono uniformemente disperse ma di lunghezza limitata, il che le rende adatte ad applicazioni che richiedono un'elevata isotropia. Le fibre di vetro piatte sono come "sottili lamiere di acciaio", con uno spessore di 3-10 μm e una larghezza di 50-200 μm, il che conferisce loro un'area di contatto con la resina da 3 a 5 volte maggiore rispetto alle fibre di vetro rotonde, migliorando direttamente la levigatezza superficiale di un grado.

Sfida di performance: chi è il tuo "tipo ideale"?

Quando si scelgono le fibre di vetro, bisogna concentrarsi sui seguenti aspetti chiave delle prestazioni:

1. Aspetto

PC riempito di fibra di vetro a scaglie:

Grazie alla sua struttura piatta a nastro, l'area di contatto con la resina PC è da 3 a 5 volte maggiore rispetto a quella di fibre di vetro rotonde dello stesso peso. Questo crea un'interfaccia fibra-resina più liscia. In combinazione con uno speciale processo di trafilatura che riduce la rugosità superficiale, la lucentezza superficiale del pezzo stampato (misurata a un angolo di 60°) può raggiungere l'80-90%, quasi una finitura a specchio del PC puro, con una quasi totale assenza di fibre flottanti visibili.

PC riempito di fibra di vetro corta:

Le fibre corte sono distribuite uniformemente, causando solo una lieve dispersione della luce. Tuttavia, la sezione trasversale rotonda delle fibre produce comunque lievi riflessi all'interfaccia fibra-resina. La lucentezza superficiale è leggermente inferiore a quella della fibra di vetro a scaglie, solitamente intorno al 70-80%. La visibilità delle fibre flottanti richiede un controllo più rigoroso del processo di stampaggio.

PC riempito con fibre di vetro lunghe:

Le fibre lunghe (6–12 mm) tendono a formare agglomerati locali durante la lavorazione. A causa dell'"effetto scheletro", si formano minuscole fessure all'interfaccia fibra-resina, causando una riflessione diffusa della luce in queste aree. La lucentezza superficiale è di soli 50–60, con conseguente finitura leggermente opaca. Questa tipologia è più adatta per componenti funzionali come gli alloggiamenti di macchinari ingegneristici, dove le prestazioni sono prioritarie rispetto all'aspetto.

2. Forza interiore: studio delle prestazioni meccaniche

La fibra di vetro lunga è senza dubbio il “campione di resistenza”. I dati mostrano che allo stesso contenuto, il PA rinforzato con fibre di vetro lunghe ha

Resistenza alla trazione superiore del 20-30%

rispetto ai compositi in fibra di vetro corta, e

la resistenza all'impatto dell'intaglio è superiore del 50-60%

, rendendolo particolarmente adatto per componenti portanti a lungo termine come

paraurti per automobili e pale di turbine eoliche

I compositi in fibra di vetro lunga Verton di LFT-G possono mantenere la resistenza agli urti anche a -40°C, un livello di prestazioni difficile da raggiungere per le fibre di vetro corte.

La fibra di vetro corta eccelle in "equilibrio". Sebbene la sua resistenza sia leggermente inferiore, offre una buona isotropia, il che significa che le prestazioni del componente sono uniformi in tutte le direzioni. Questo la rende ideale per componenti di precisione come ingranaggi e connettori.

La fibra di vetro a scaglie (piatta) migliora leggermente la tenacità laterale. Ad esempio, l'utilizzo di fibra di vetro a scaglie per rinforzare le miscele Si-PC per le custodie degli smartphone può aumentare la resistenza alle cadute del 40%, evitando difetti come la sporgenza delle fibre.

3. Stabilità dimensionale: la chiave per il controllo della deformazione

Fibra di vetro lunga: il suo “effetto scheletro” trattiene saldamente la resina, riducendo il restringimento lungo la direzione del flusso fino a un minimo di

0,15%

Tuttavia, le differenze di restringimento nella direzione perpendicolare possono essere significative, rendendo i pannelli piatti di grandi dimensioni soggetti a deformazioni.

Fibra di vetro corta: il restringimento è più uniforme, il che la rende adatta a parti di piccole e medie dimensioni.

Fibra di vetro a scaglie (piatta): grazie alla sua struttura piatta, garantisce un controllo più equilibrato sul restringimento nel piano, rendendola la scelta ideale per i pannelli interni delle automobili.

4. Difficoltà di elaborazione

Fibre lunghe: tendono ad aggrovigliarsi, richiedendo attrezzature per stampaggio a iniezione ad alte prestazioni. Gli stampi necessitano di canali e punti di iniezione di grandi dimensioni (≥3 mm) e i pezzi complessi possono richiedere processi a bassa pressione come l'iniezione e compressione (ICM), lo stampaggio di schiuma strutturale (SFM) o lo stampaggio a iniezione assistita da gas (GAIM). In caso contrario, la rottura delle fibre può ridurre drasticamente le prestazioni.

Fibra di vetro corta e fibra di vetro a scaglie (piatta): sono più facili da lavorare con metodi consolidati e collaudati. Possono essere stampate su macchine a iniezione standard e i gradi ad alta fluidità possono riempire anche pareti sottili fino a 0,5 mm. La fibra di vetro a scaglie, grazie al suo buon aspetto superficiale, può ottenere un'estetica migliore rispetto alla fibra di vetro corta senza la necessità di temperature di stampaggio più elevate.

Scenari applicativi: posizionare la fibra di vetro giusta nel posto giusto

Non esiste una fibra di vetro "migliore", ma solo la scelta più adatta. Diamo un'occhiata ai principali ambiti di utilizzo dei diversi tipi di fibre di vetro:

Fibra di vetro lunga:

Il “campione dei carichi pesanti” delle applicazioni industriali.

Componenti come staffe per telai di autoveicoli, alloggiamenti di macchinari e attacchi per sci, che devono resistere a impatti e carichi a lungo termine, sono realizzati al meglio con fibre di vetro lunghe. I compositi in fibra di vetro lunghe utilizzati nelle staffe per cavi possono durare 10 anni sottoterra senza corrosione, risolvendo completamente i problemi di ruggine delle staffe metalliche. Le plastiche rinforzate con fibre di vetro lunghe sono ideali anche per i pedali delle automobili.